NW Wood 540

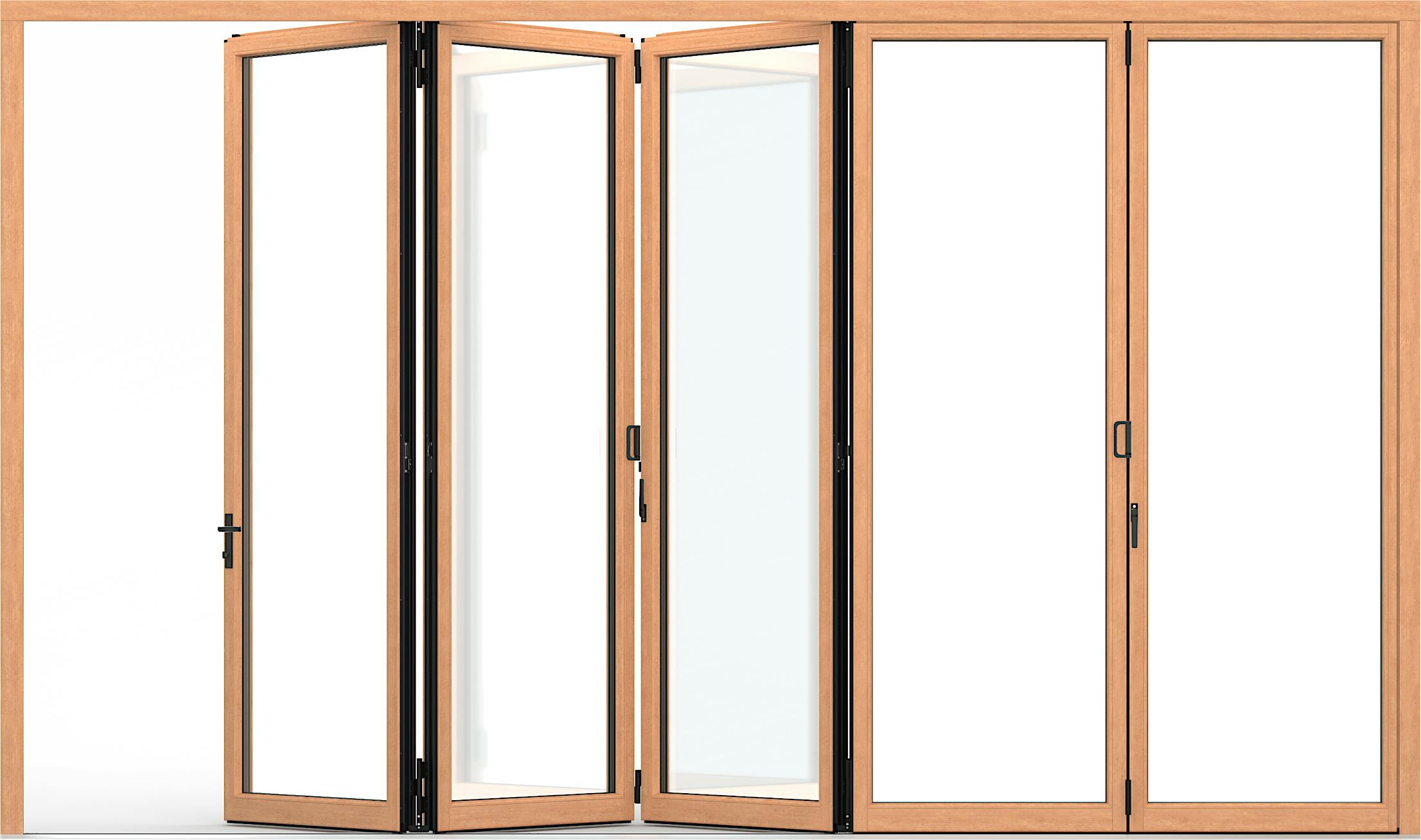

Slimmest Wood Framed Folding Glass Door

- Quadruple laminated, cross-grained, narrow wood frame delivers exceptional energy efficiency

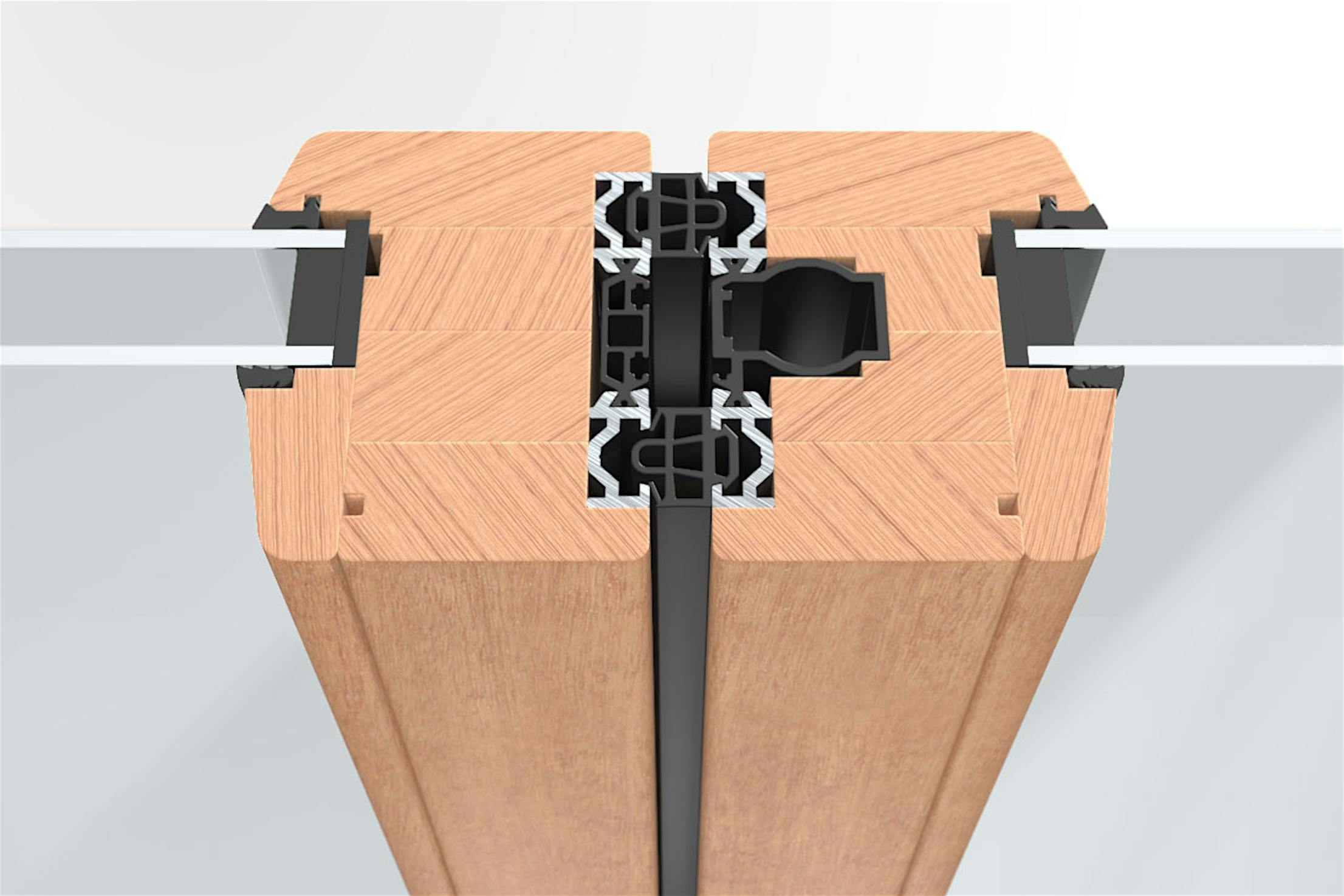

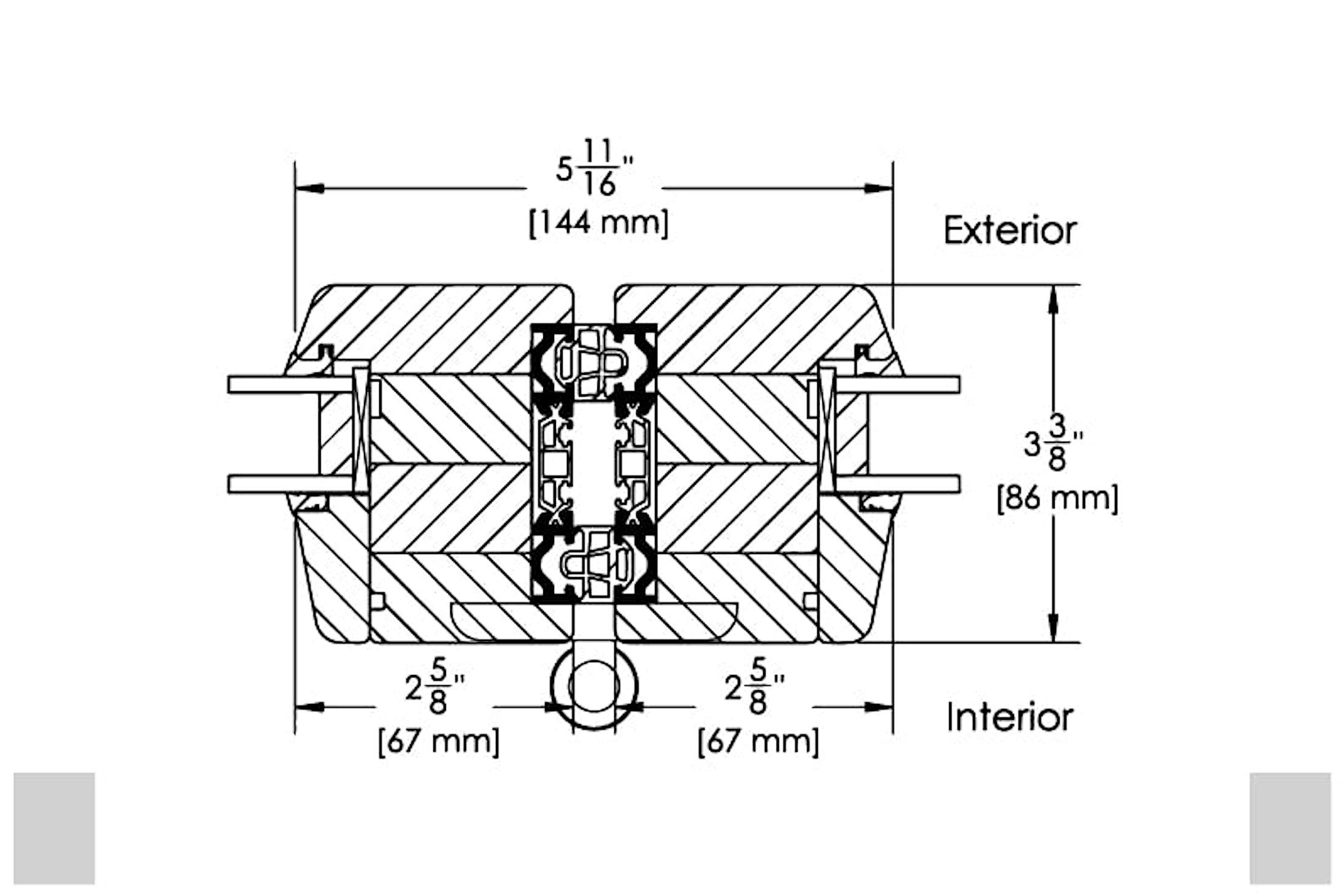

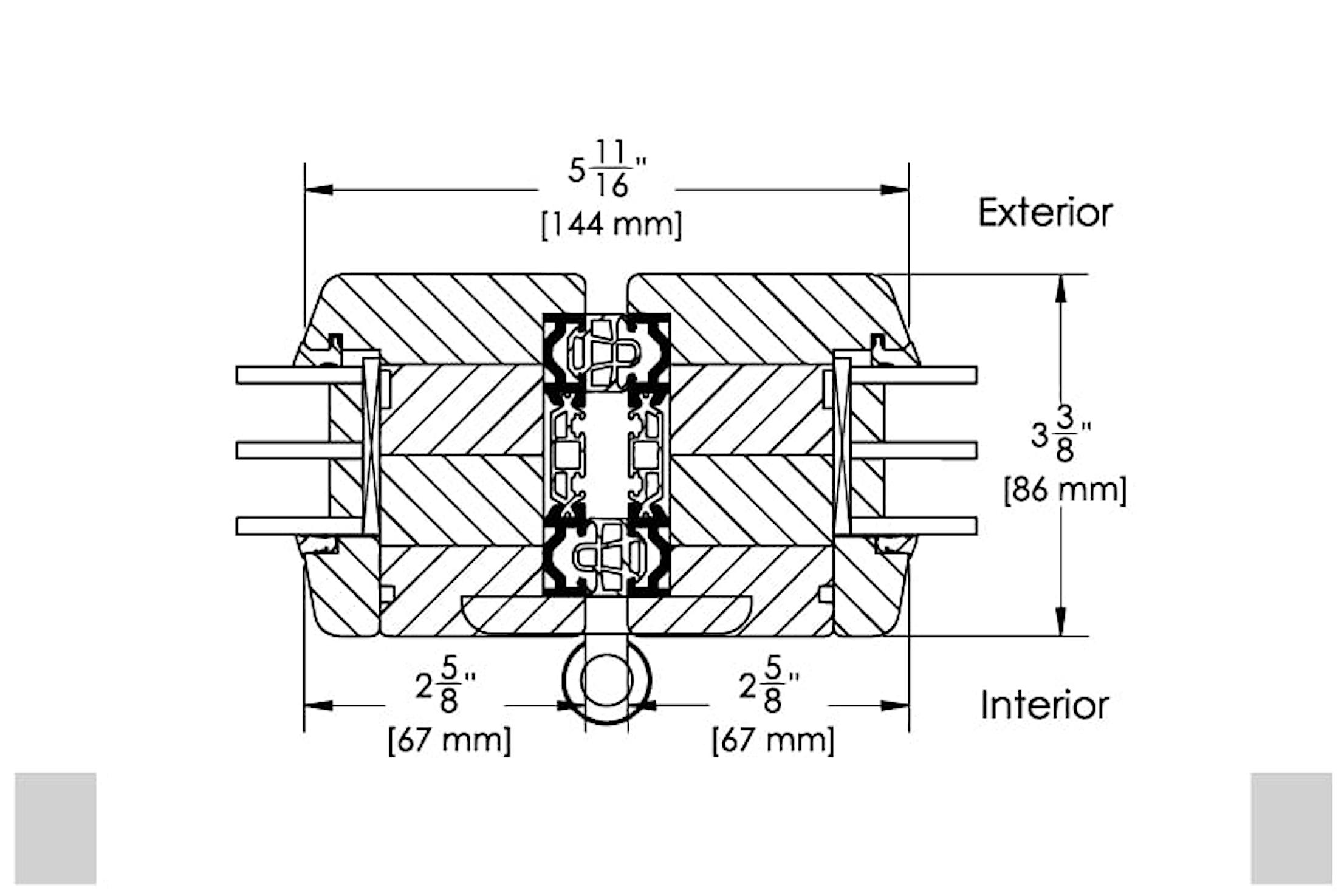

- Intersection of two folding panels is 5 11/16″ (144 mm)

- Floor supported panels capable of heights up to 9′ 10″ (3000 mm)

Slimmest Wood Framed Folding Glass Door

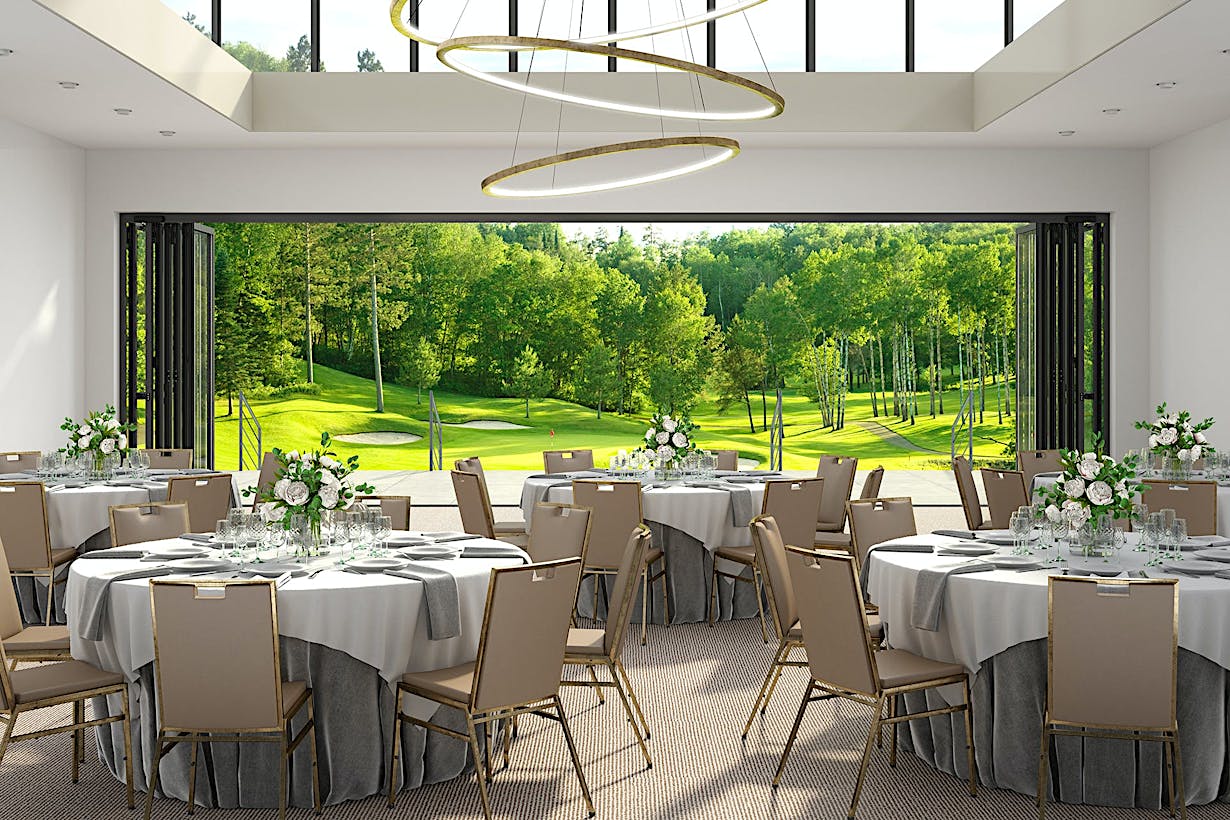

NW Wood 540 provides the slimmest wood frame in the folding door industry. With a quadruple laminated cross-grained wood frame profile styled in a subtly rounded design, the intersection of two folding panels is a mere 5 11/16" (144 mm). This floor supported system offers an extremely streamlined appearance with minimal exposed hardware, creating a new level of aesthetics.

Fourth Generation Thermally Efficient Wood Framed Folding Glass Door

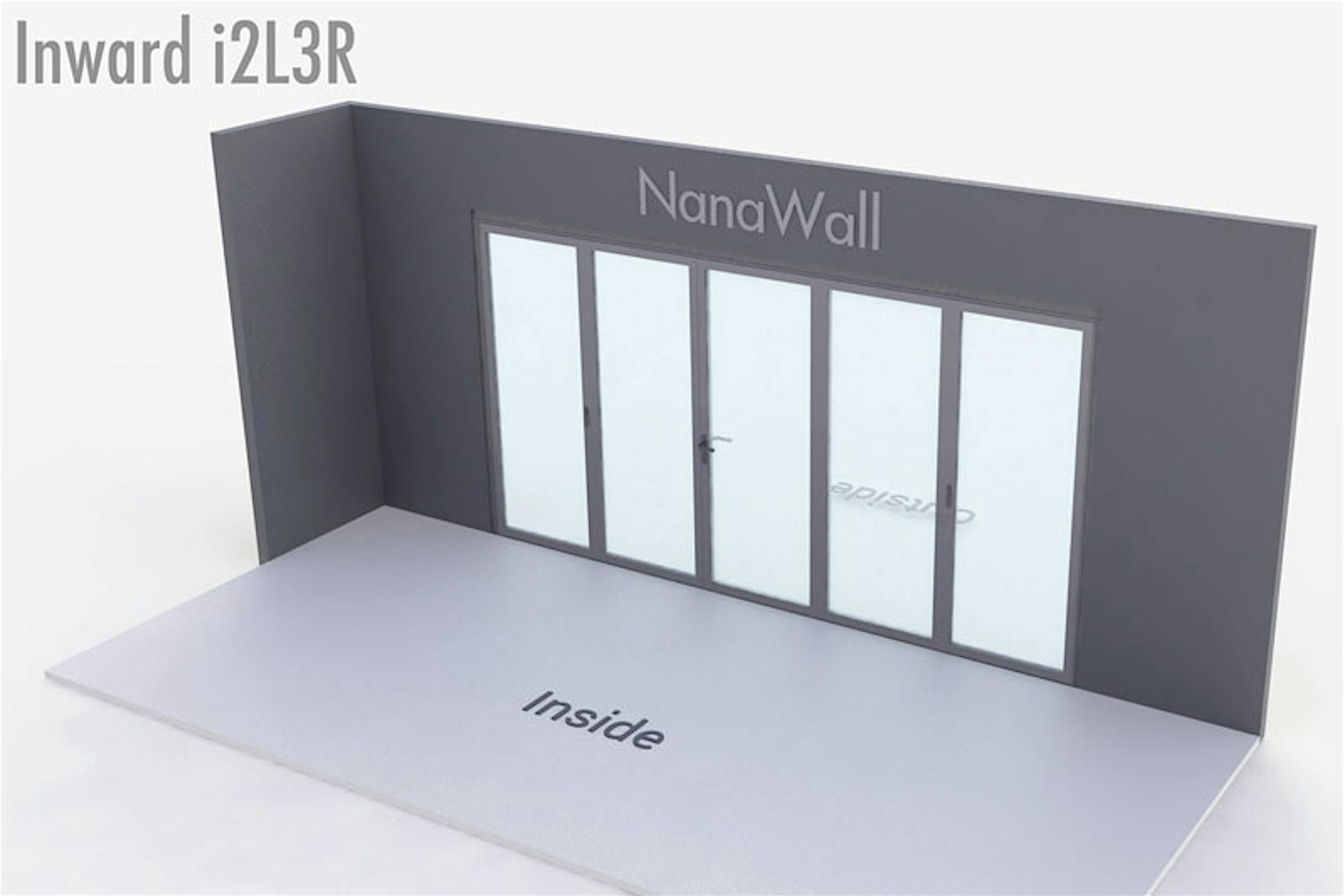

Floor-supported panels reach heights up to 9'10" (3000 mm) and support inswing, outswing, open corner, and custom configurations. Designed for energy efficiency and weather protection, NW Wood 540 delivers comfort, security, and independently verified performance.

Broad Product Configurability

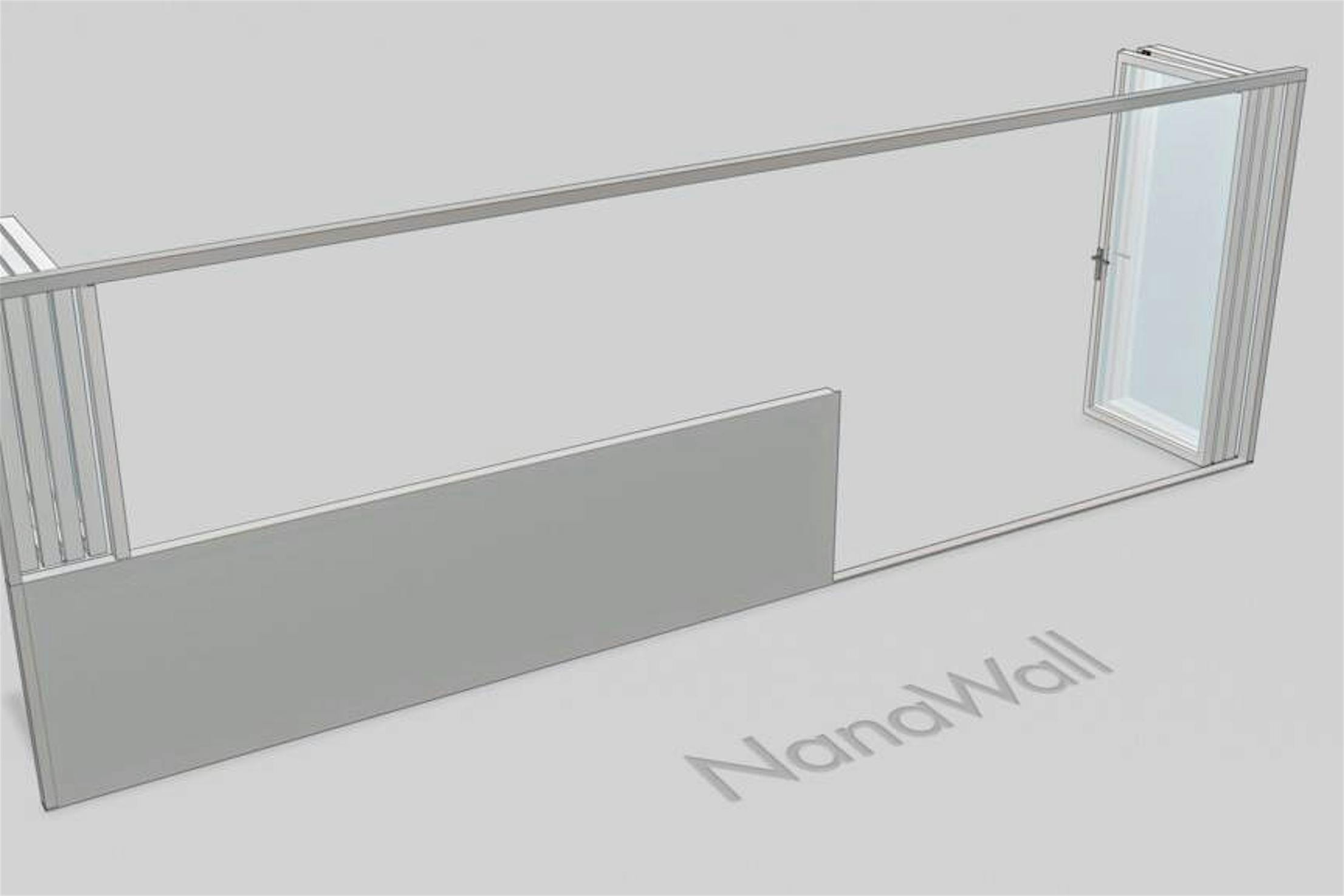

Panel sets are able to move and stack either to the right, left, or center within the same track allowing the panels to be stacked in the most convenient location as needed.

NW Wood 540 is built with quadruple laminated cross-grained solid premium wood to achieve the tall, slim-framed panel design of this next generation wood system. The quadruple-layer laminated wood allows for larger panel sizes, creates structural integrity, and provides long-term durability. Unlike other systems on the market, NanaWall wood framed systems are built on solid single-species wood frames and are not veneered over inferior wood, allowing for sanding and refinishing down the road as needed. NW Wood 540 is manufactured with sustainably harvested wood options that meet the international standards of PEFC.

NW Wood 540, along with the Generation 4 Folding Glass Walls by NanaWall product family, is the only floor supported folding system available that allows for larger opening sizes and flexible space management with the integration of FourFold or SixFold Panel Sets. These panel sets can move and stack either to the right, left, or center within the same track allowing the panels to be stacked in the most convenient location as needed.

Floor supported systems are ideal for applications where load-bearing capability of the header is a concern.

- Provides long-term durability and smooth operation.

- Control construction costs. Requires less header load and limits the need for extensive pre-cambering.

- Improves the likelihood of keeping existing header when retrofitting/remodeling.

To accommodate traffic flow, swing panels up to 3′ 3″ (1000 mm) can be added either to the end of a chain of panels for systems with an odd number of panels folding in one direction or hinged to the side jamb, depending on unit height and configuration.

Swing panels have been tested and passed over 500,000 cycles and can be optionally outfitted with higher kickplates for ADA compliance. Top door closers by others are possible.

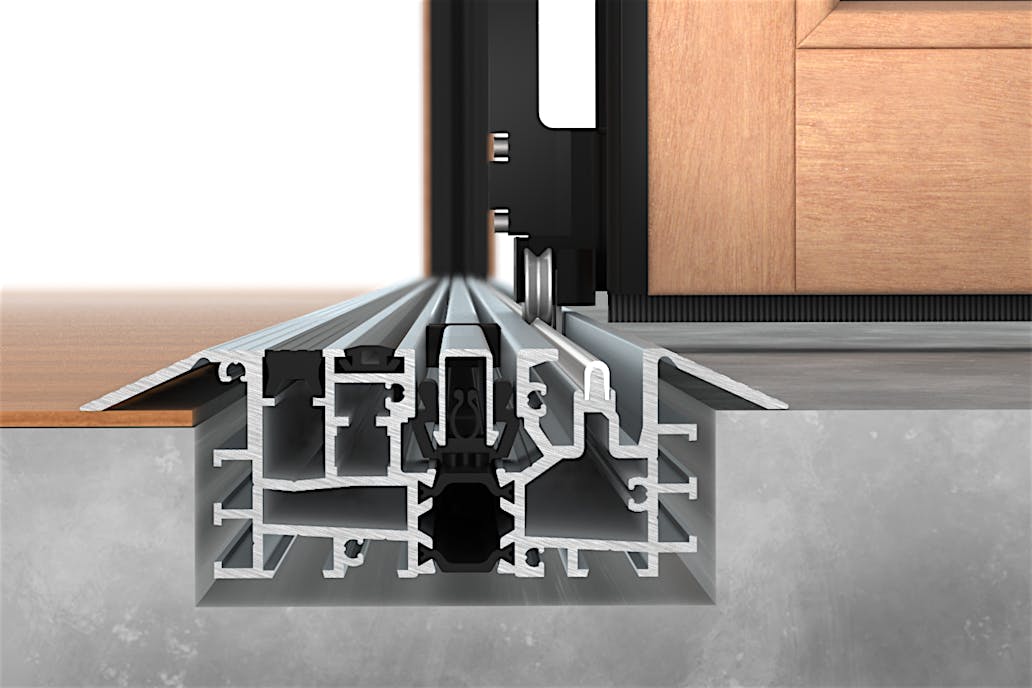

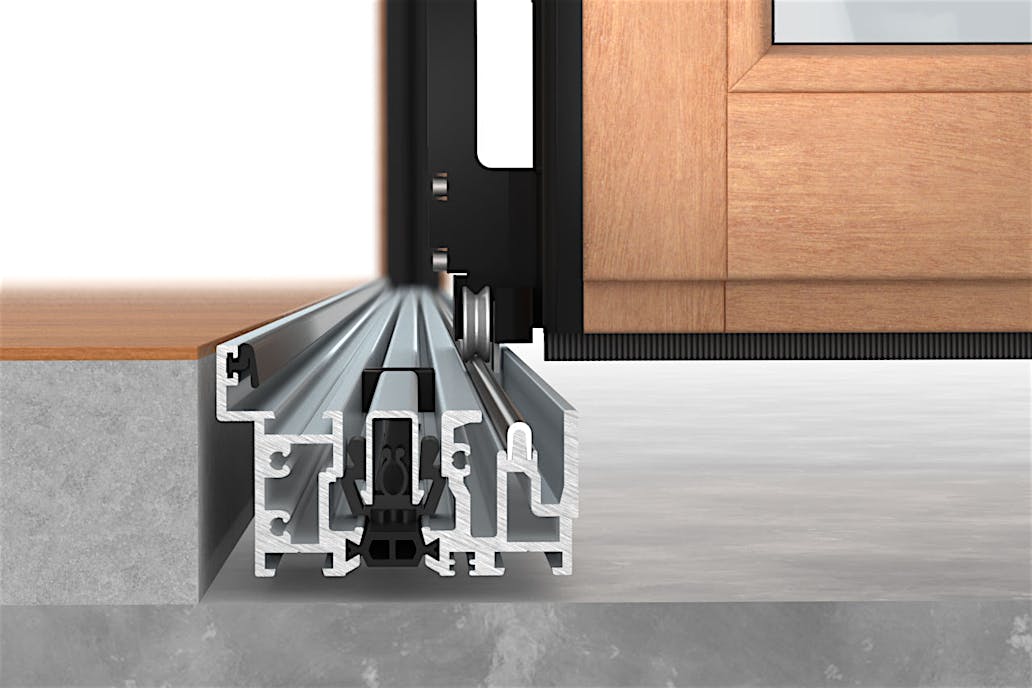

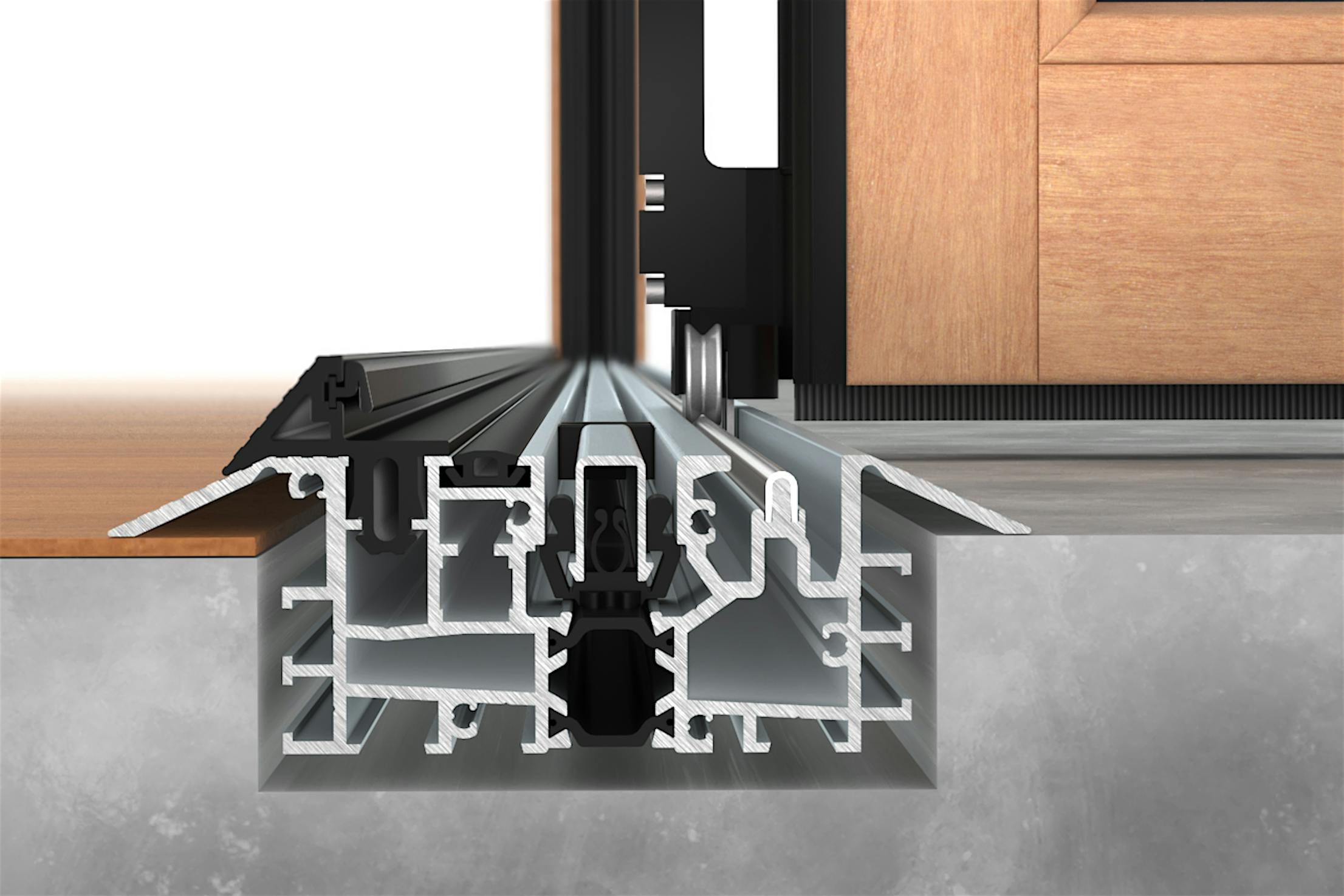

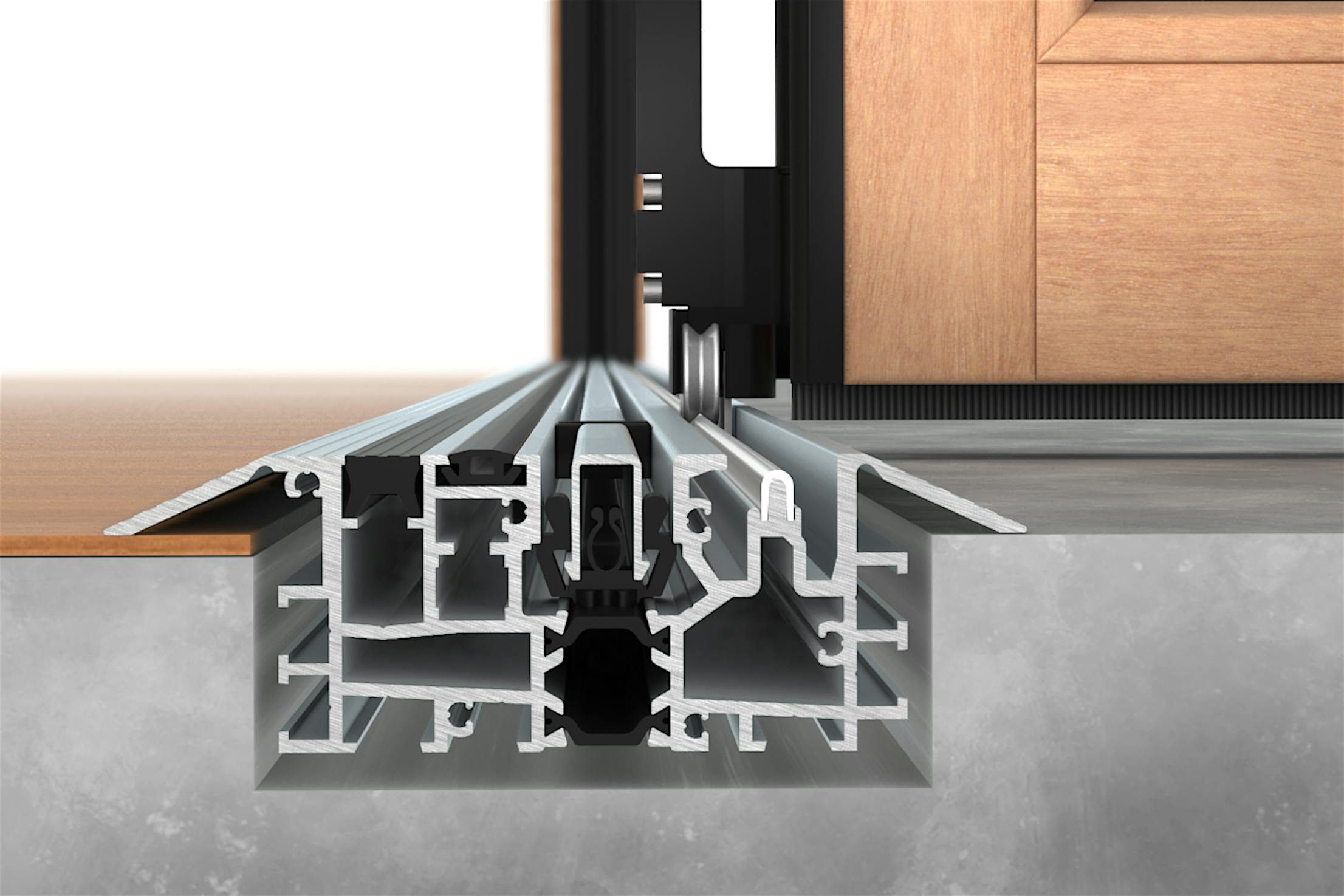

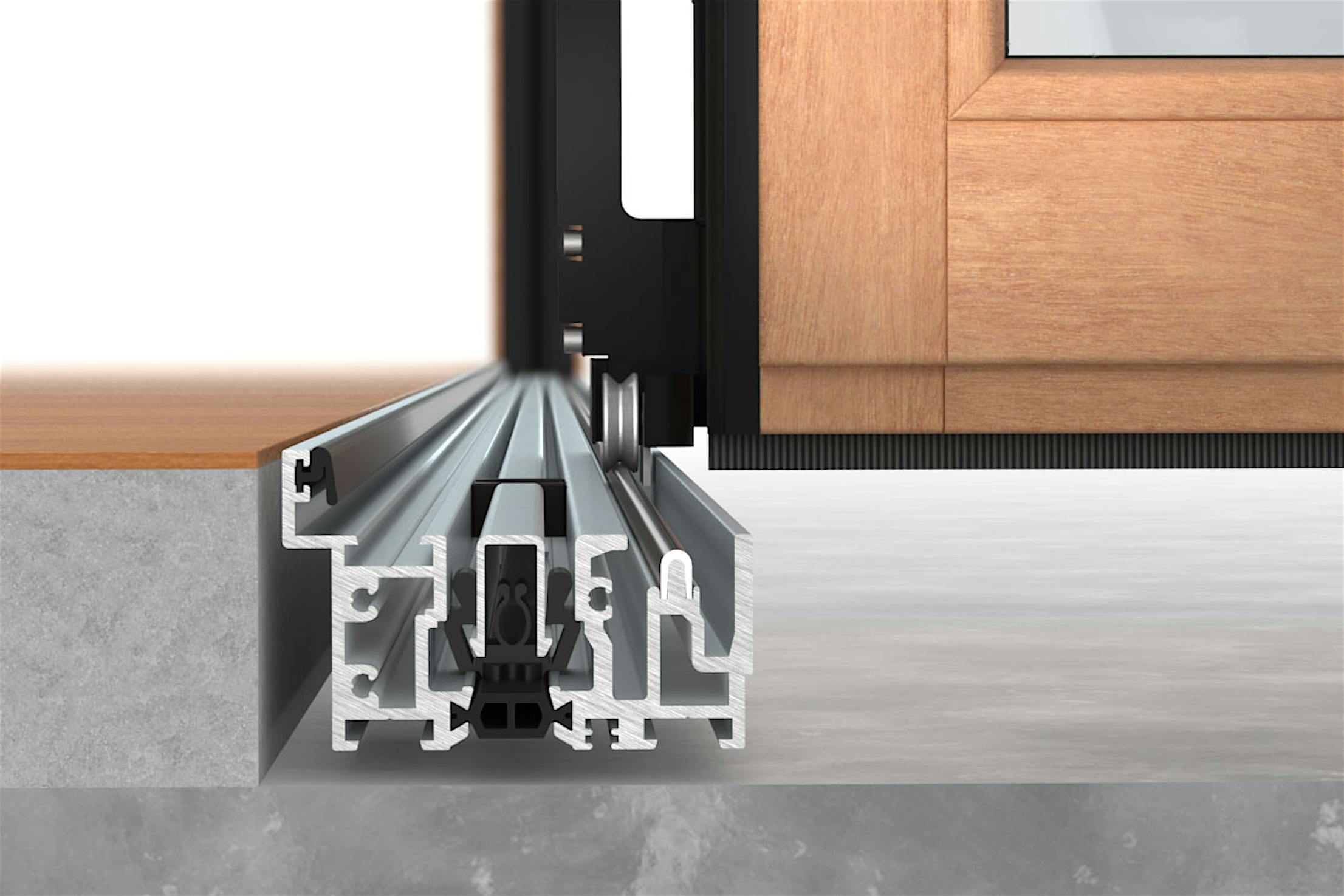

Three Sill Options with High Heel Resistant Feature

NW Wood 540 has three sill options: Performance, Low Profile Saddle Sill, Low Profile Saddle Sill with UniverSILL®. Standard to all sills is removable aluminum high heel resistant sill inserts. These inserts provide ADA compliance for the Low Profile Saddle, and create a very barefoot-friendly transition.

Sill Options

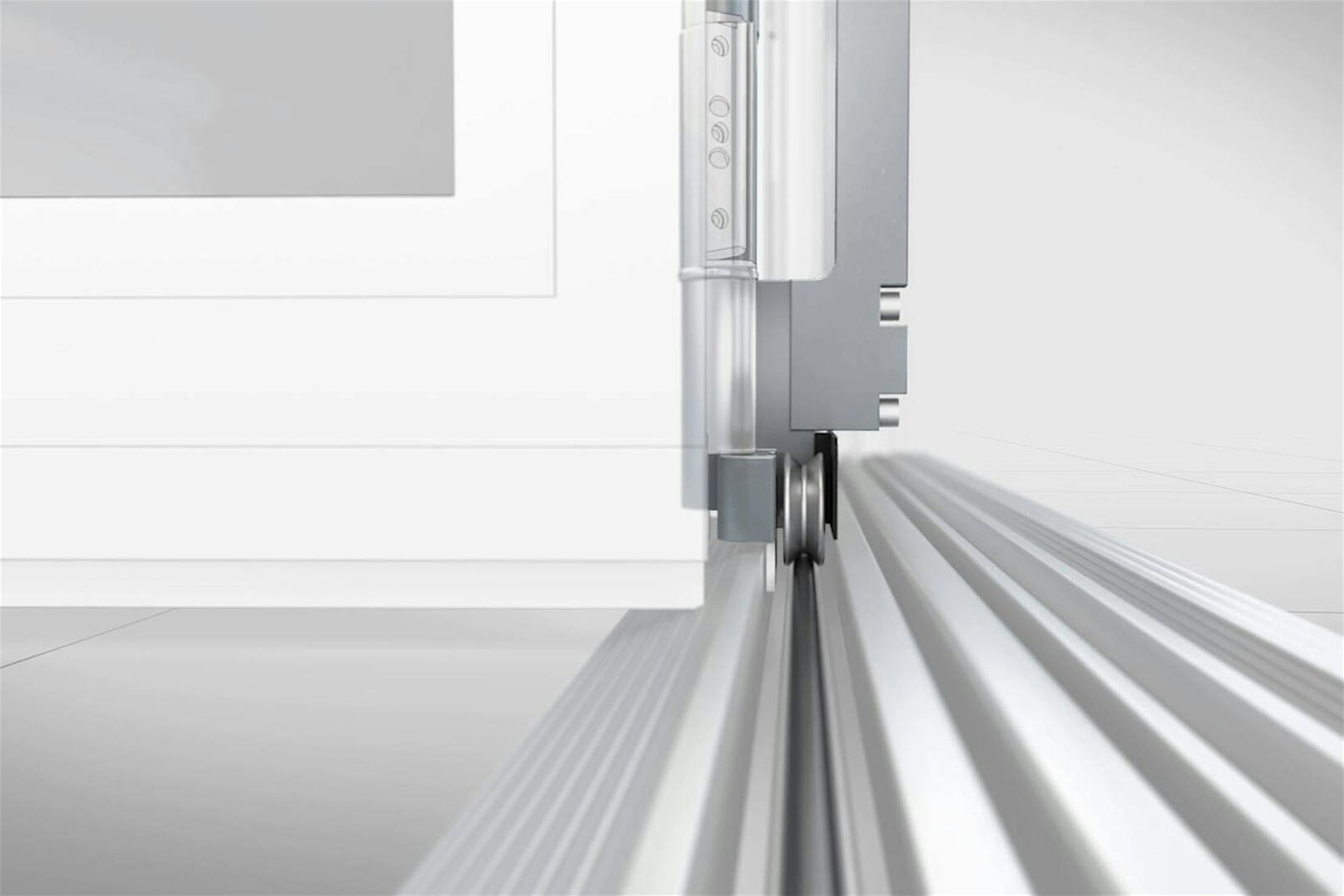

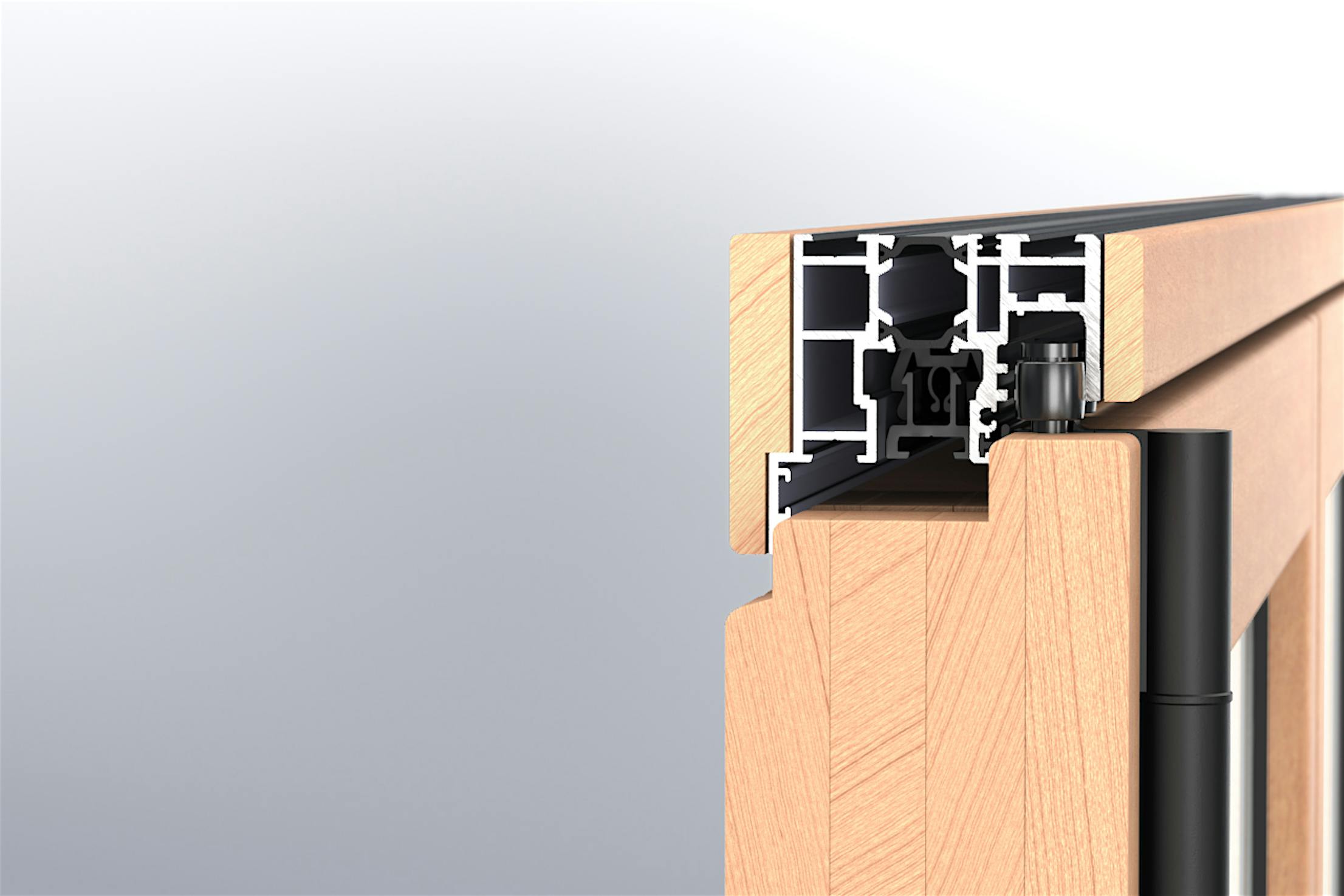

Unique Gothic Arch Roller

The running carriage rolls above the water table on two stainless steel wheels with a unique Gothic arch design supported by a double row of ball bearings. With a 2-point contact of each wheel to the floor track, the system glides quietly and smoothly with less friction by providing an equal distribution of weight on the stainless steel track.

Explore the Features and Benefits of Generation 4

Click on a hotspot to learn more.

- Stainless steel for clean appearance with sealing cushion to avoid thermal conductivity

- Provides optimal load transfer so less connection points required

- For enhanced aesthetics, all frame attachment points are hidden

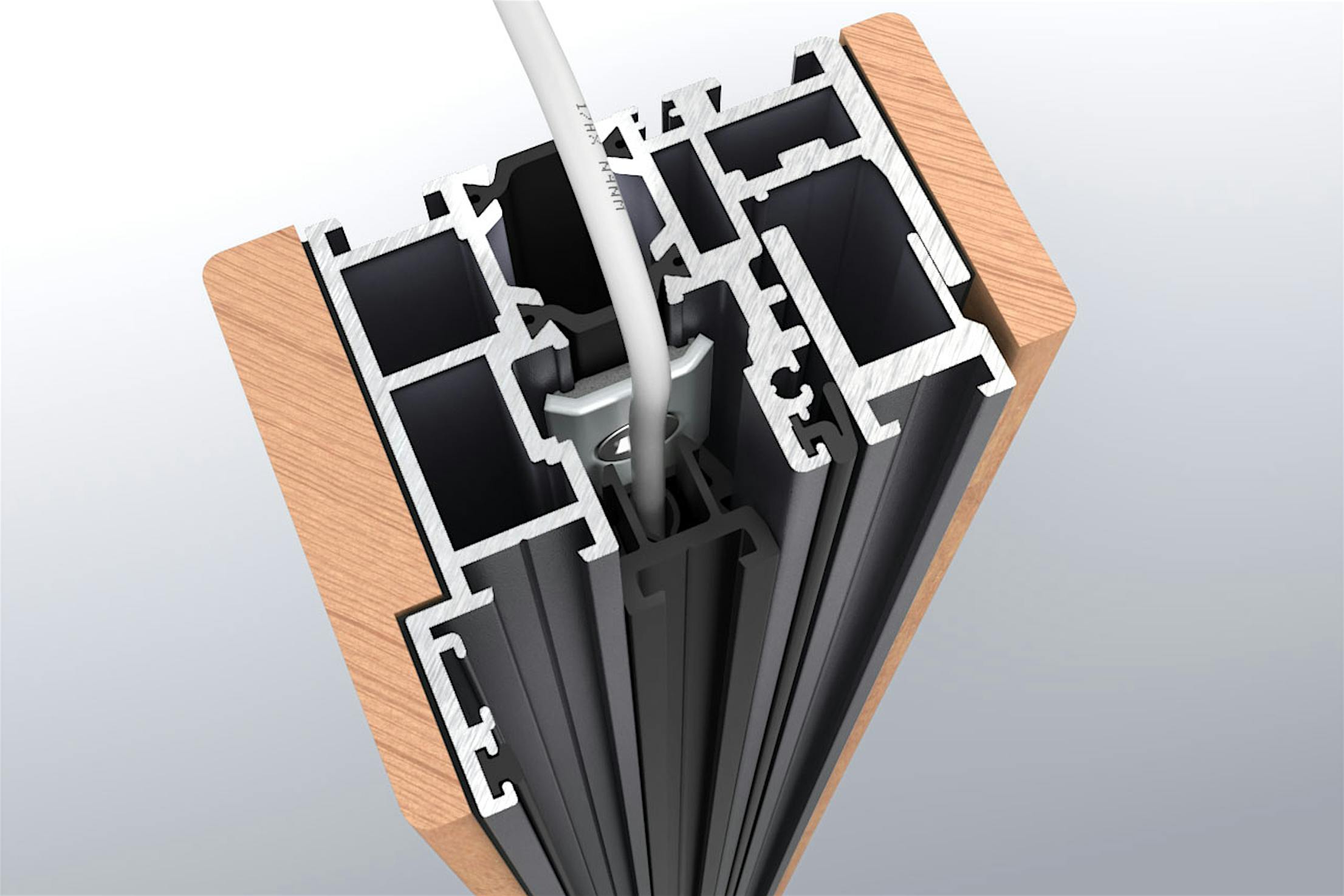

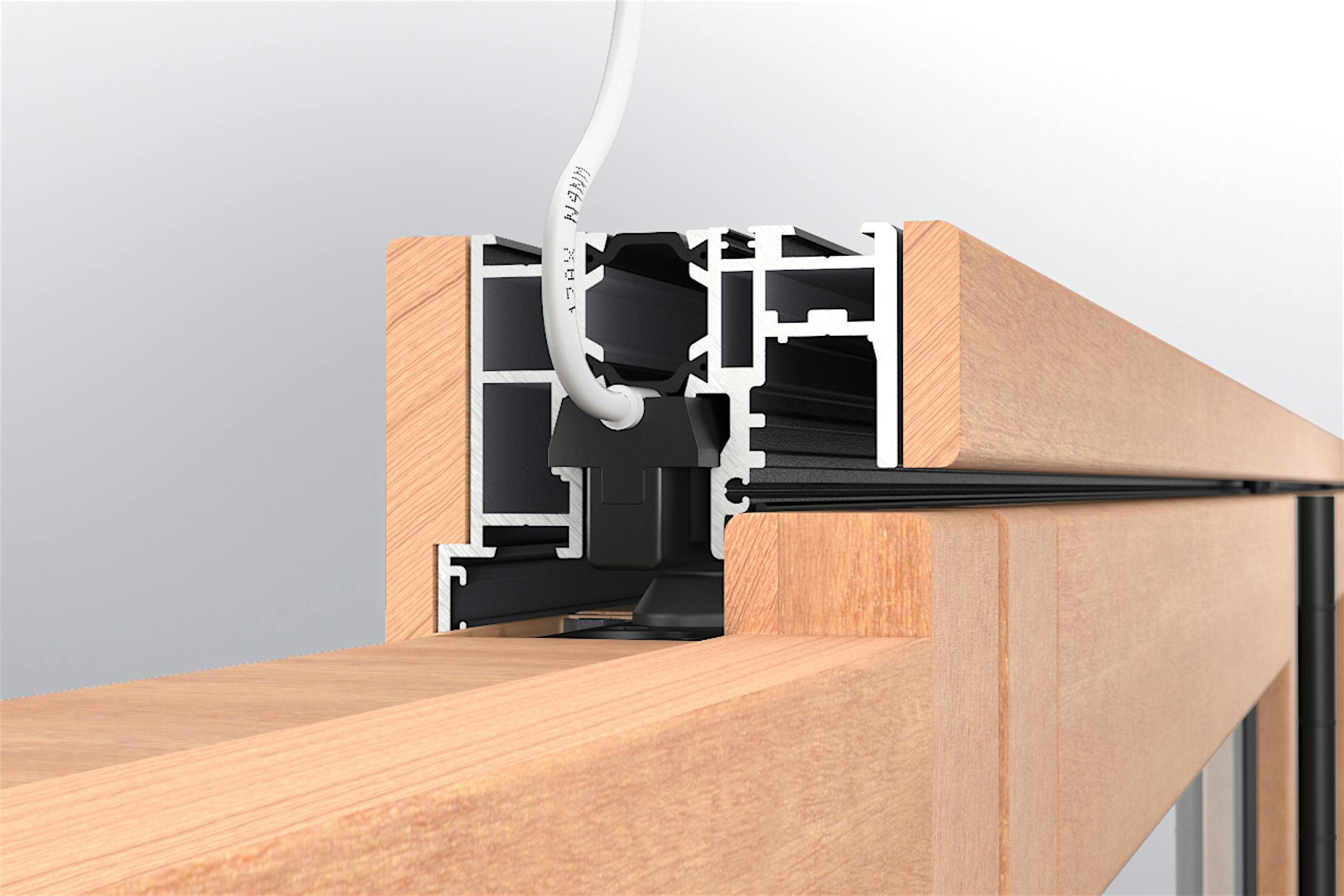

- Offers space for concealed cable routing for security systems by others

- Patented lateral adjustment of +/- 3/16″(5 mm) to allow for construction tolerance

- Adjusts easily should extreme panel expansion/contraction occur

- Panel guide helps system glide through head track with smooth operation

- System operated on floor supported technology for ease of movement

- Proprietary engineered component stacks FourFold and SixFold panel sets neatly and securely when in open position

- Allows for dynamic stacking of panels at the left, right, or center of opening operating on Floor Supported Technology

- Lock monitoring is available with Reed contact (by others) and specialized magnetic locking rod end cap to connect to home security systems

- Can be connected to count opening/closing cycles to identify when maintenance should be performed (by others)

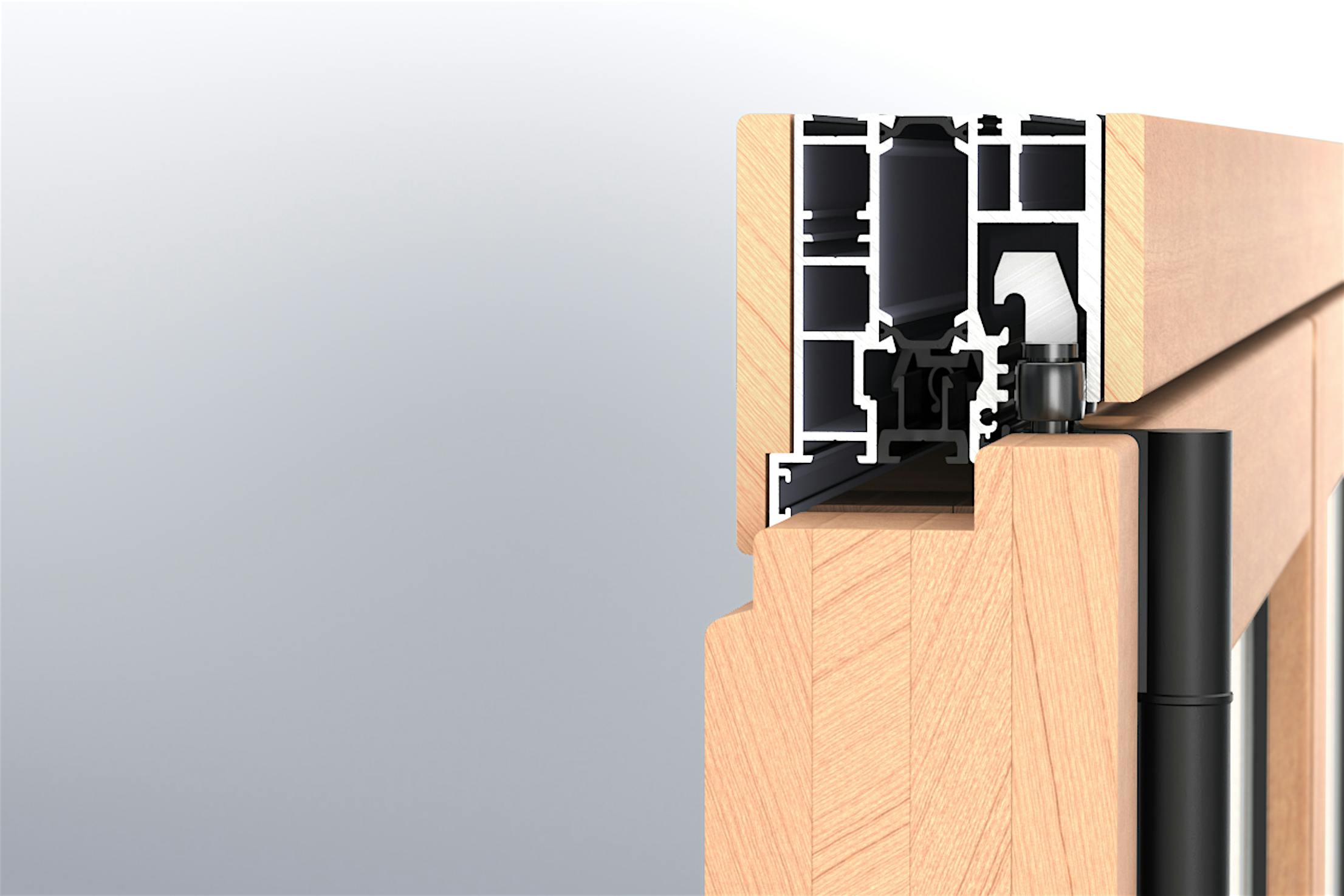

- Subtly rounded profile design for a modern aesthetic

- Intersection of two folding panels is a mere 5 11/16″ (144 mm) for minimal sightlines

- Flat handle multi-point secure locking with 1″ (24 mm) throw bolt top and bottom

- Built on solid single-species wood frames not veneered over inferior wood, unlike others on the market

- Allows for larger panel sizes, creates structural integrity, and provides long-term durability

- Sustainably harvested wood options meet PEFC standards

- Hidden spring-loaded TwinX mechanism aligns panels over 7′ (2150 mm)

- Patented TwinX interlocks panels and provides structural reinforcement to eliminate exposed hinges in the middle of the system

- Creates barefoot and heel friendly transitions while protecting from debris accumulation in floor track

- Provides ADA compliance for Low Profile Saddle and Flush sills

- Produces channel for LED rope light floor illumination (by others)

- Available for outswing only

- Thermally broken, provided with high heel resistant insert

- Easily convert Saddle Sill into a higher weather rated sill for enhanced water and air protection as needed

- Unique Gothic arch roller design for effortless operation

- Outswing shown, inswing also available

- Thermally broken, ADA compliant, high heel and barefoot friendly

- Sufficient water rating provided

- Unique Gothic arch roller design for effortless operation

- Outswing shown, inswing also available

- Thermally broken, provided with high heel resistant insert

- Built for higher water rating and weather resistance with compression gasketing on all sides

- Unique Gothic arch roller design for effortless operation

Extreme Weather Resistant

Energy-efficient by design, our glass walls keep the elements at bay, ensuring that even as seasons or temperatures change, your interior comfort will always remain the same.

Certified Testing Standards

NanaWall products endure the latest AAMA testing standards for air, water, structural, and forced entry.

Highly Energy-Efficient

Designed to keep the elements at bay, holding warmth inside while acting as a transparent barrier to the weather outside.

Materials Transparency

This product contributes to multiple LEED rating systems and has HPD certification.

Download Declaration Documents

Test Results

Inside Generation 4 walls are innovations designed to meet the challenges of wind, water, extreme temperatures, forced entry, and structural load. Besides housing the system’s locking rods, our Bionic Turtle®—a patented, single-piece insulbar design—provides an exceptional insulating thermal break between the frame profiles: adding energy efficiency and year-round comfort.

Florida Product Approval # FL41107

See Air, Water, Structural, Thermal, and Forced Entry Results

Greater Security With Enhanced Energy Efficiency

Designed for energy efficiency and strong weather performance, the best-in-class NW Wood 540 provides exceptional protection from outside elements and delivers comfort and security when closed. As a NanaWall product, the NW Wood 540 has been put through rigorous independent performance testing for air, water, structural, and forced entry.

What Our Customers Have to Say

Brooklyn Brownstone - Case Study

Creating the New Family Living Space for homeschooling, COVID-19 safe open-air play dates, dining area and outdoor movie night.

Lumen - Case Study

Opening glass walls allowed Lumen Detroit to continue operations in the face of Covid lockdowns while maintaining customer loyalty and revenue.

“Given the choice of multi-leaf partition systems, there really are few products with the proven track record to sustain the day-to-day use of an automotive retail environment—which is why we chose NanaWall.”

— Erich "Deeg" Snyder, Gensler, Architect

To ensure the longevity of our wood systems, we provide triple and quadruple laminated cross-grains to accommodate the wood’s natural expansion and contraction.

See Wood Options

NW Wood 540 has three sill options: Performance, Low Profile Saddle, Low Profile Saddle with UniverSILL®.

Standard to all sills is removable aluminum high heal resistant sill inserts. These inserts provide ADA compliance for the Low Profile Saddle sill and create a very barefoot-friendly transition. Furthermore, the inserts offer protection from dirt and debris collecting in the bottom track.

See Sill Options

Standard to the system is concealed locking between folding panels that operates with a 180° turn of a flat handle.

See Locking Options

The system comes standard with continuous seals along the face of each panel frame. Furthermore, standard to each system are two levels of insulating thermal breaks for optimal defense from heat and cold. For projects requiring even more protection, an optional third level may be added. The glass pocket is able to accommodate glass from 7/8" (22 mm) double glazed to 2 7/16" (62 mm) double or triple glazed insulated glass. All glazing is reduced iron (LT 89). Please contact NanaWall Systems for more details.

See Glazing Options

Stylish Handles in Multiple Finishes

Our handles are both functional and stylish and can be customized to accentuate your space and reflect your style.

See Handle Options

Generation 4 Tilt Turn and Fixed Windows

Generation 4 Tilt Turn and Fixed window systems offer concealed hinge hardware and the same clean lines as our accordion glass doors.

Generation 4 Tilt Turn and Fixed Windows

Retractable Screens

A retractable screen add-on is perfect for blocking bugs while providing privacy and fresh air. Screens are not available through NanaWall Systems.

Retractable Screens

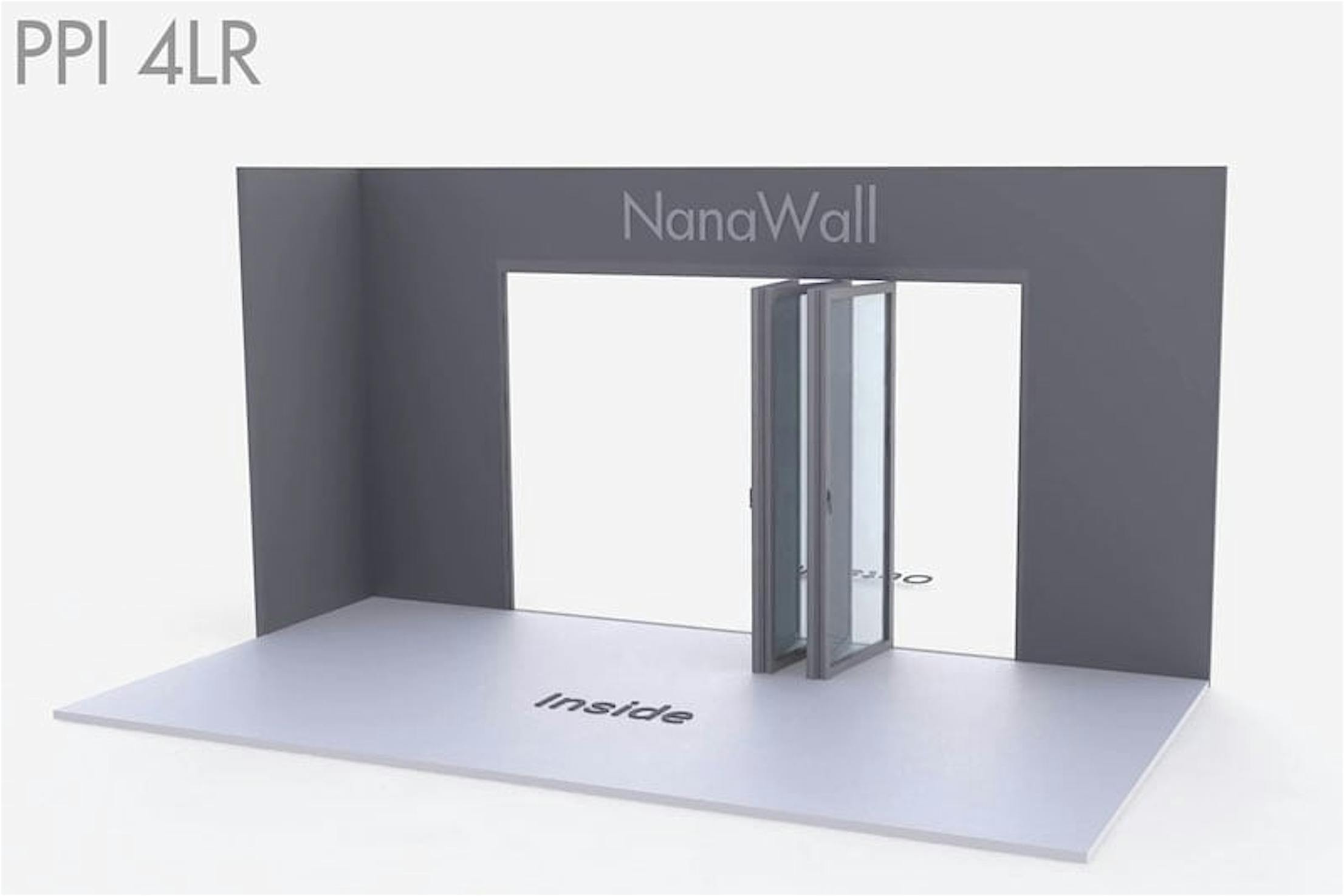

Over 90 standard configurations for straight forward folding systems.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

FourFold and SixFold Panel Sets are able to move and stack either to the right, left, or center within the same track allowing the panels to be stacked in the most convenient location as needed.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

Combine a NanaWall Folding Windows with a NanaWall Folding Glass Wall seamlessly

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

All standard configurations are available in cornerless options.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More ConfigurationsWe consider ourselves your partners from day one. Connect immediately with a NanaWall expert to answer your questions and explore how we can support your project.

(866) 210-4285

Monday - Friday: 7 AM - 5 PM PST