SL70

Aluminum Framed Folding Glass Door Designed to Solve Specific Architectural Challenges and for Demanding Commercial Applications.

- Floor supported, tall panel system designed for heavy-duty weather performance and high traffic applications

- Features a vertical running post for structural reinforcement, ease of operation, and long-term commercial use

- Can be configured with segmented curves and 90° - 135° open corners

Superior Performance Anywhere

The NanaWall SL70 meets or exceeds the most extreme performance requirements making it suitable for virtually any location in the world.

Comfort in Cold Climate Excels in Wind Driven Rain

The NanaWall SL70 is NFRC certified and can meet or exceed Energy Star standards in all climate zones. Additionally, it has achieved high ratings in both static and dynamic water testing.

Commercially Rated for High Traffic Areas

The NanaWall SL70 is highly durable and is designed for high traffic areas. Panic hardware and self-closing device compatible. The swing door has been tested for 500,000 cycles without failure

Architect Jonathan Feldman shares his insights from the award-winning Butterfly House project and how using the floor supported NanaWall SL70 contributed to the success of his overall design.

Explore Floor Mounted Folding Doors

Capable of reaching heights of up to 12′ (3650 mm) tall, SL70 is an acoustic glass wall system suitable for interior applications such as schools, offices, medical facilities and hospitality spaces. Providing interiors with flexibility, transparency, and acoustical buffering, SL70 is sound-rated up to STC 42.

The NanaWall SL70 offers curved walls as well as cornerless configurations for more creative design solutions.

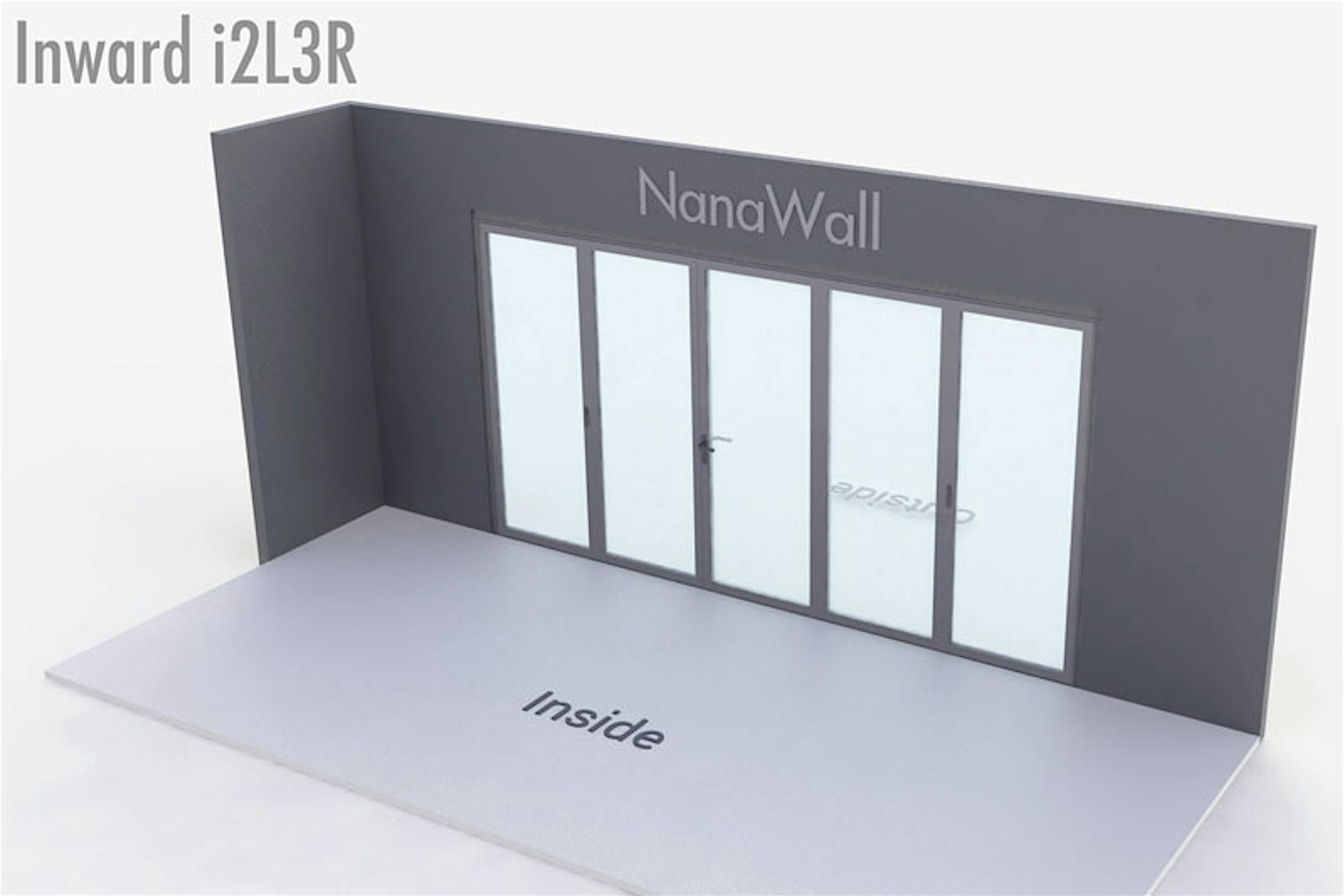

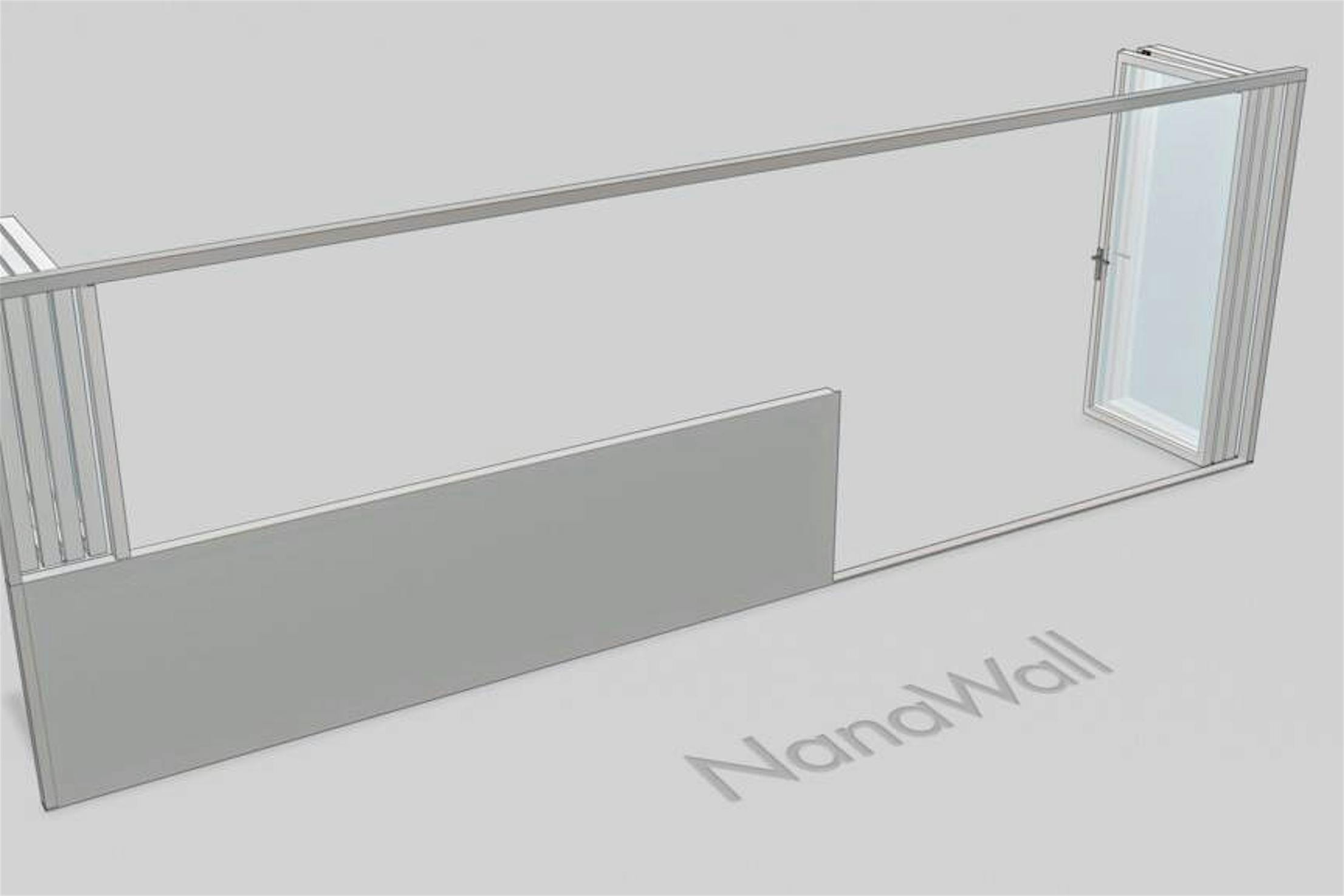

Sample of possible configurations

Segmented Curve Capabilities

A key feature is the ability to create a segmented curve utilizing the flat glass panels to achieve a curved aesthetic. Segmented curves of 6° - 12° can be created with or without an integrated swing door and 90° - 135° open corner configurations.

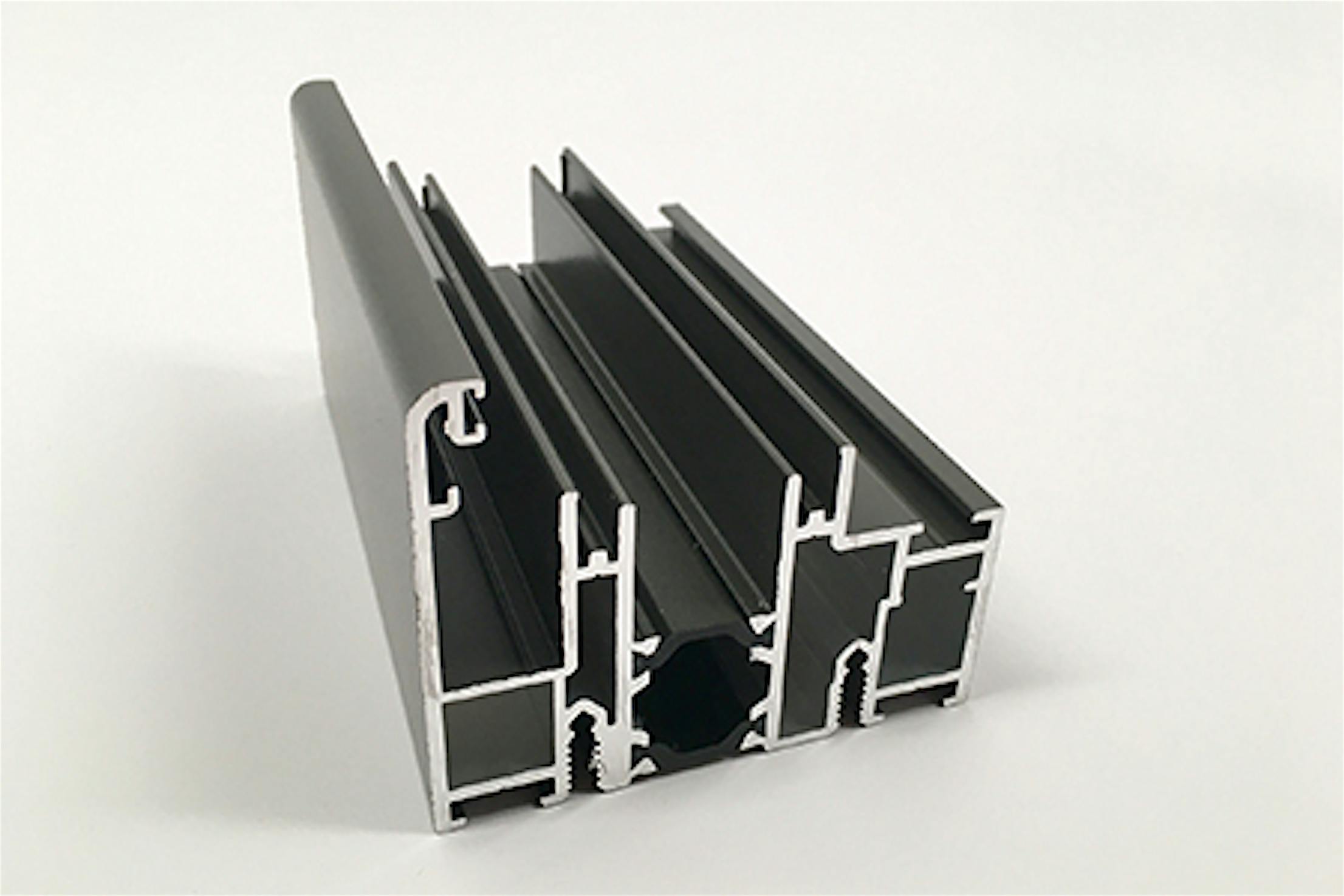

Running Post Provides Extra Strength

The NanaWall SL70 incorporates a post between each door panel—this design adds structural strength and allows for long-term commercial operation.

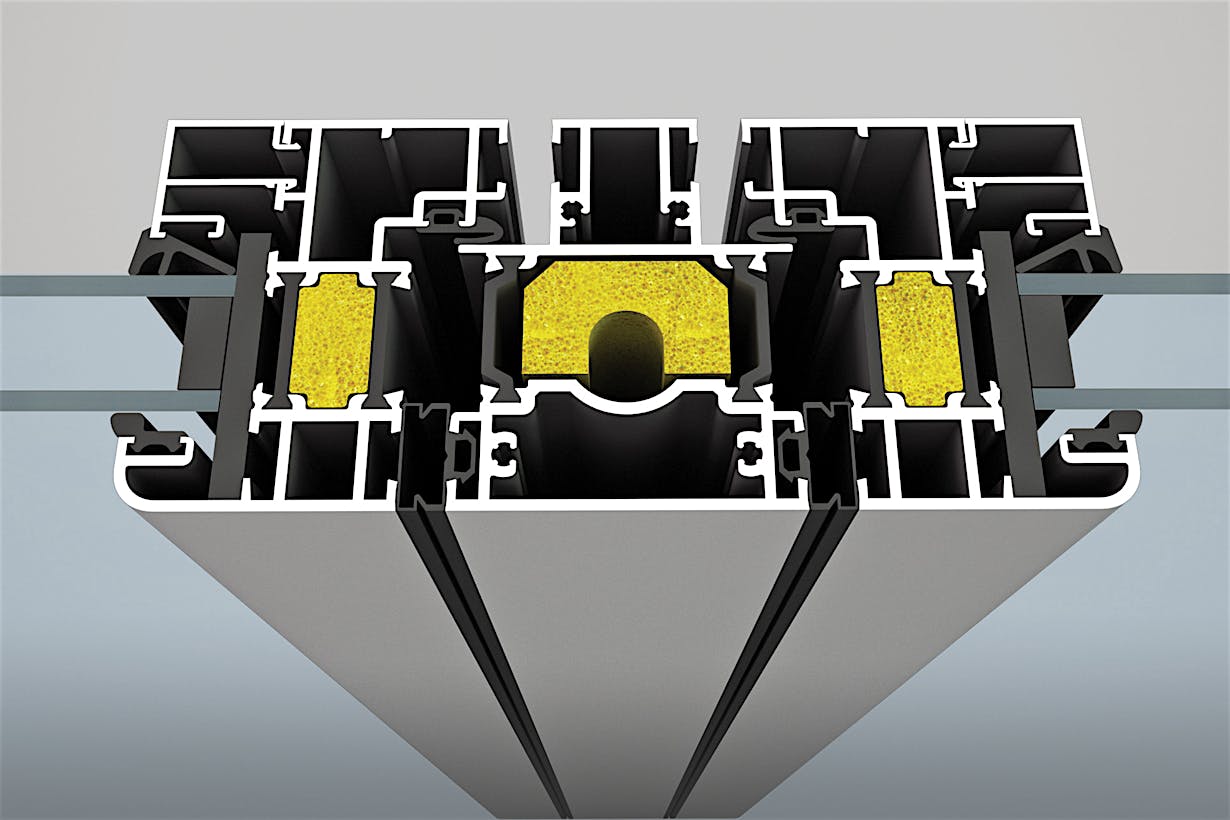

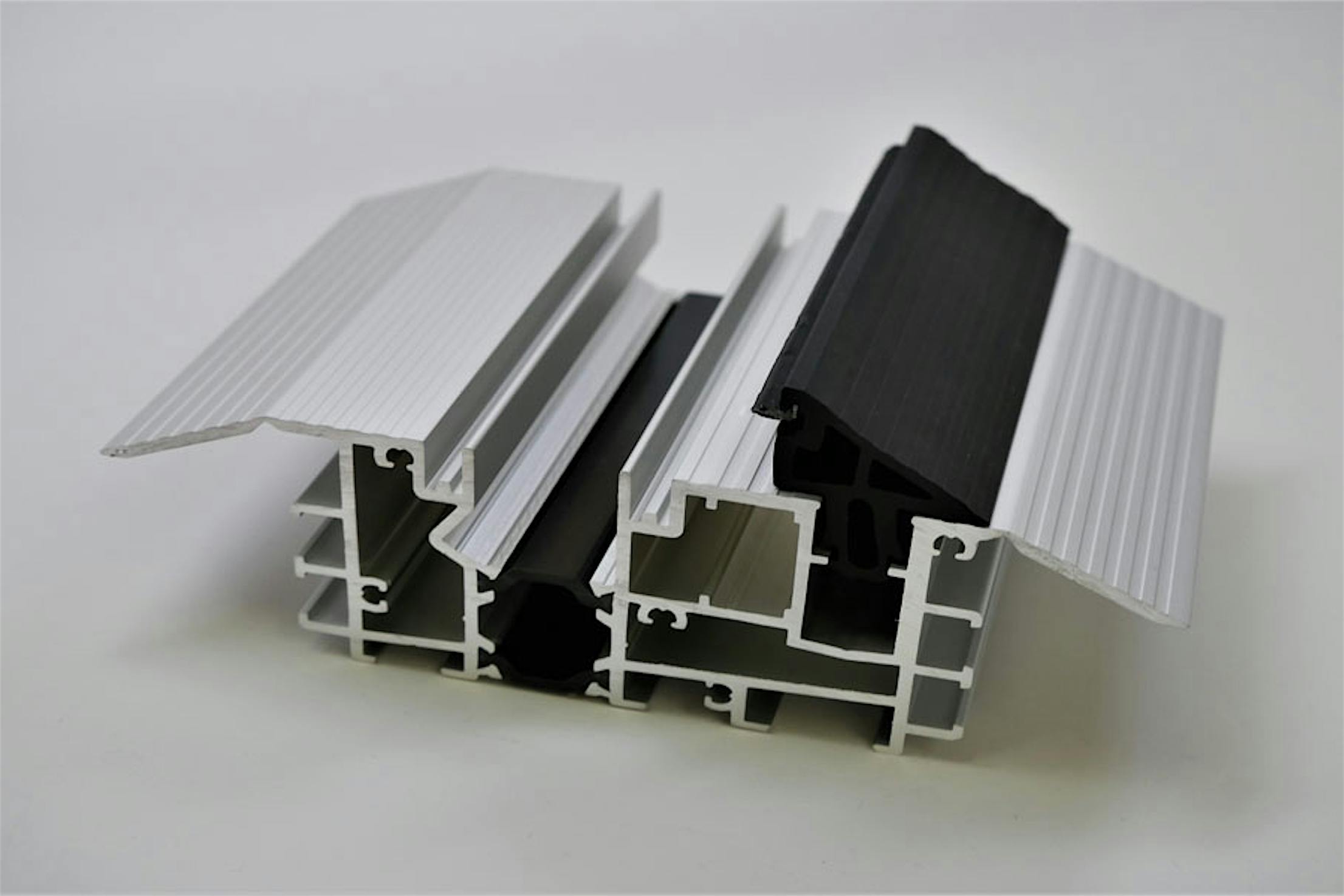

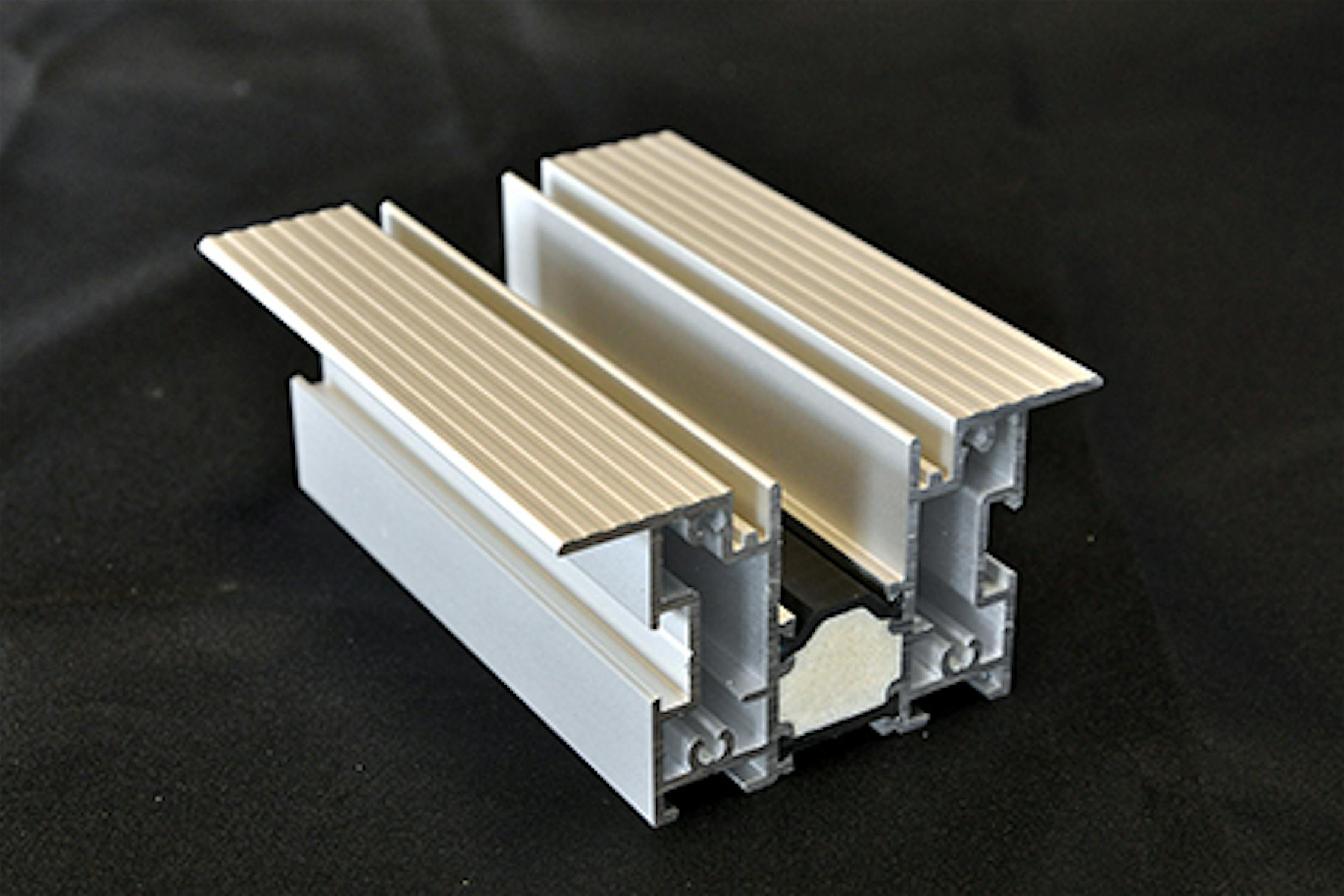

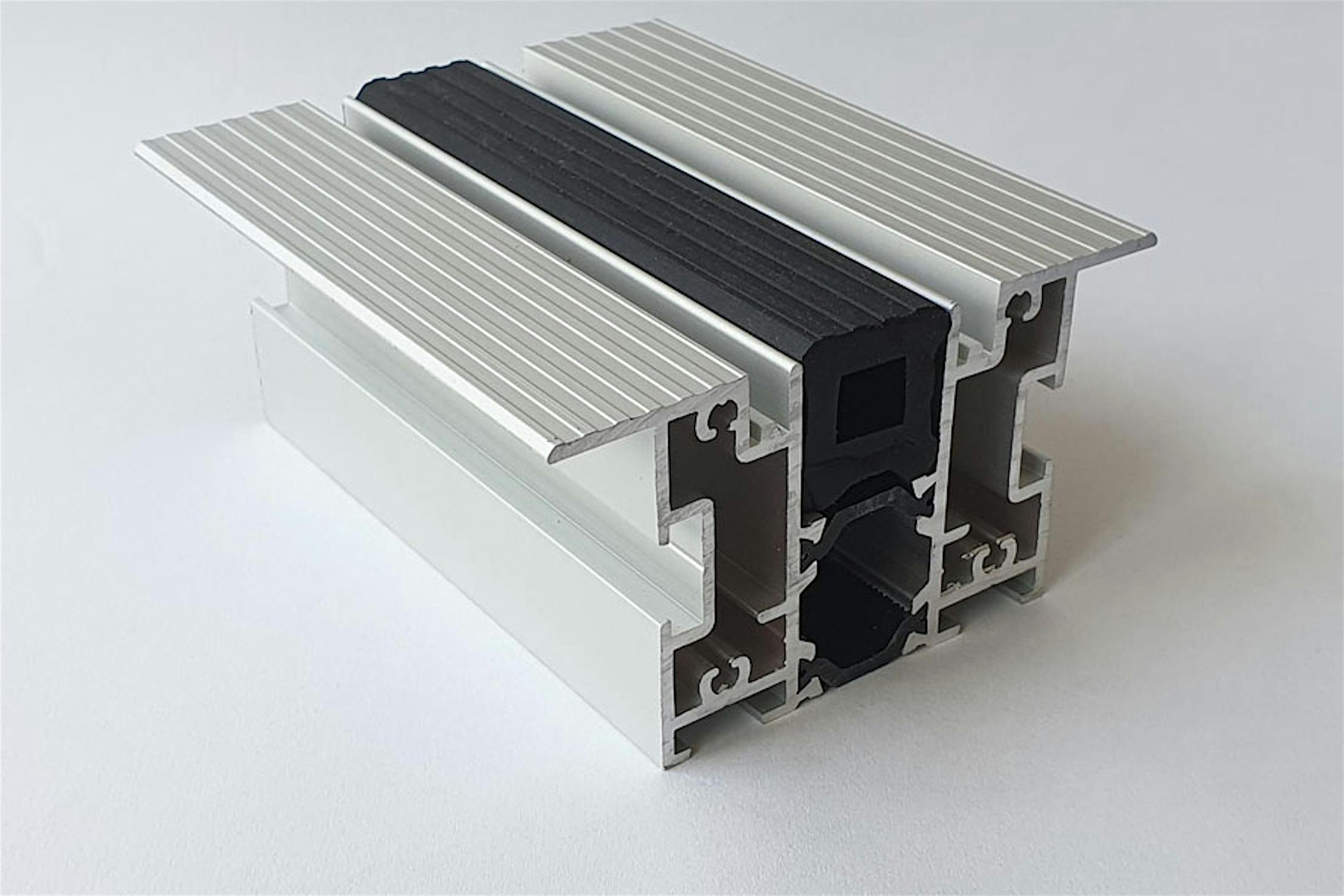

Insulated Aluminum Core

The NanaWall SL70 features an all aluminum design that incorporates a thermal barrier built-in. With an overall depth of 70mm, this provides exceptional protection from exterior elements and delivers a comfortable and quiet indoor experience when closed

Extreme Weather Resistant

Energy-efficient by design, our glass walls keep the elements at bay, ensuring that even as seasons or temperatures change, your interior comfort will always remain the same.

Certified Testing Standards

NanaWall products endure the latest AAMA testing standards for air, water, structural, and forced entry.

Highly Energy-Efficient

Designed to keep the elements at bay, holding warmth inside while acting as a transparent barrier to the weather outside.

Materials Transparency

This product contributes to multiple LEED rating systems and has HPD certification.

Download Declaration Documents

Test Results

NanaWall SL70 has been independently tested for air and water penetration resistance, structural deflection, and forced entry.

Florida Product Approval # FL35025

See Air, Water, Structural, Thermal, and Forced Entry Results

Acoustic Performance

NanaWall SL70 has been tested at an accredited and certified independent laboratory. We test our product to meet the highest standards of ASTM E90, ISO 10140-1, 2, 4, 5. STC calculations meets standards of ASTM E413, and ISO 717-1.

Acoustical Performance ResultsWhat Our Customers Have to Say

Butterfly House

A stunning Monterey County home, the Butterfly House by Feldman Architecture seamlessly blends indoor-outdoor living with NanaWall SL70 folding glass walls.

Gloria's Restaurant

NanaWall gives Gloria’s Restaurant the opportunity to transform an elegant interior dining room into a unique, al fresco dining experience in a matter of seconds.

“NanaWall allowed us to create uninterrupted views to the Chesapeake Bay and open the west wall of the Loblolly House, effectively transforming the interior of the house into a porch.”

— Marilia Rodrigues, KieranTimberlake, Architect

50 standard colors that come at no additional cost, with an additional 200+ colors to choose from.

See Finish Options

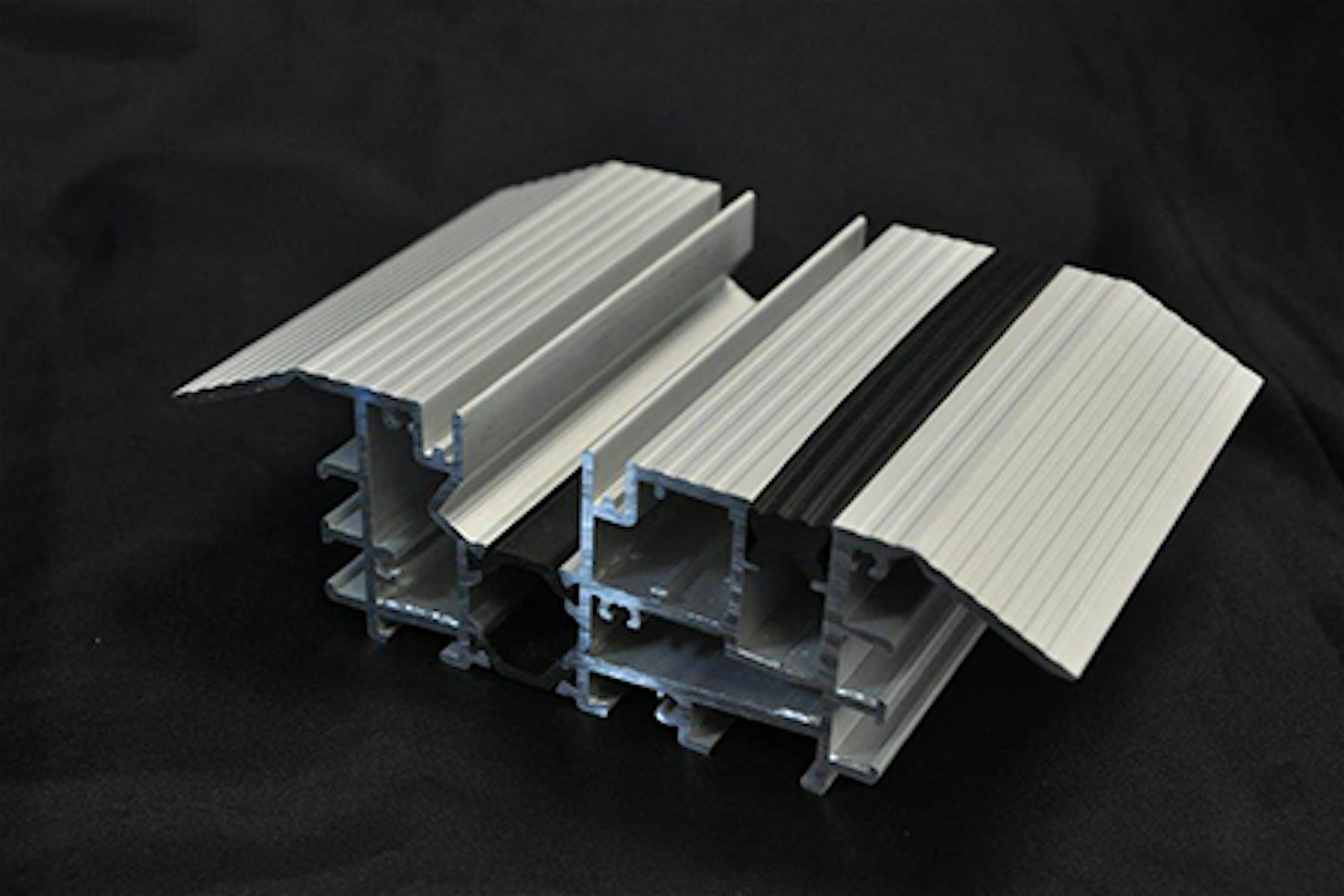

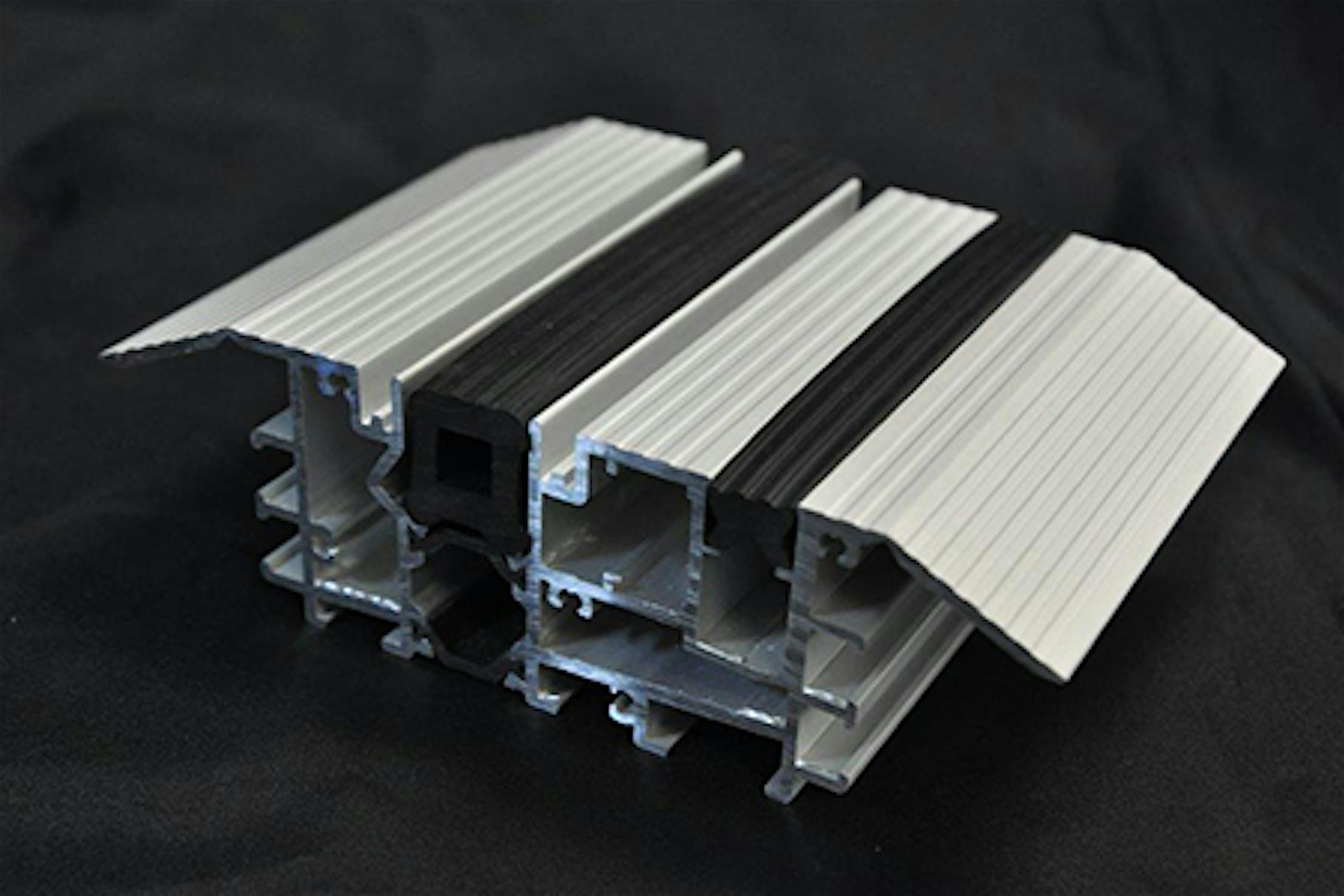

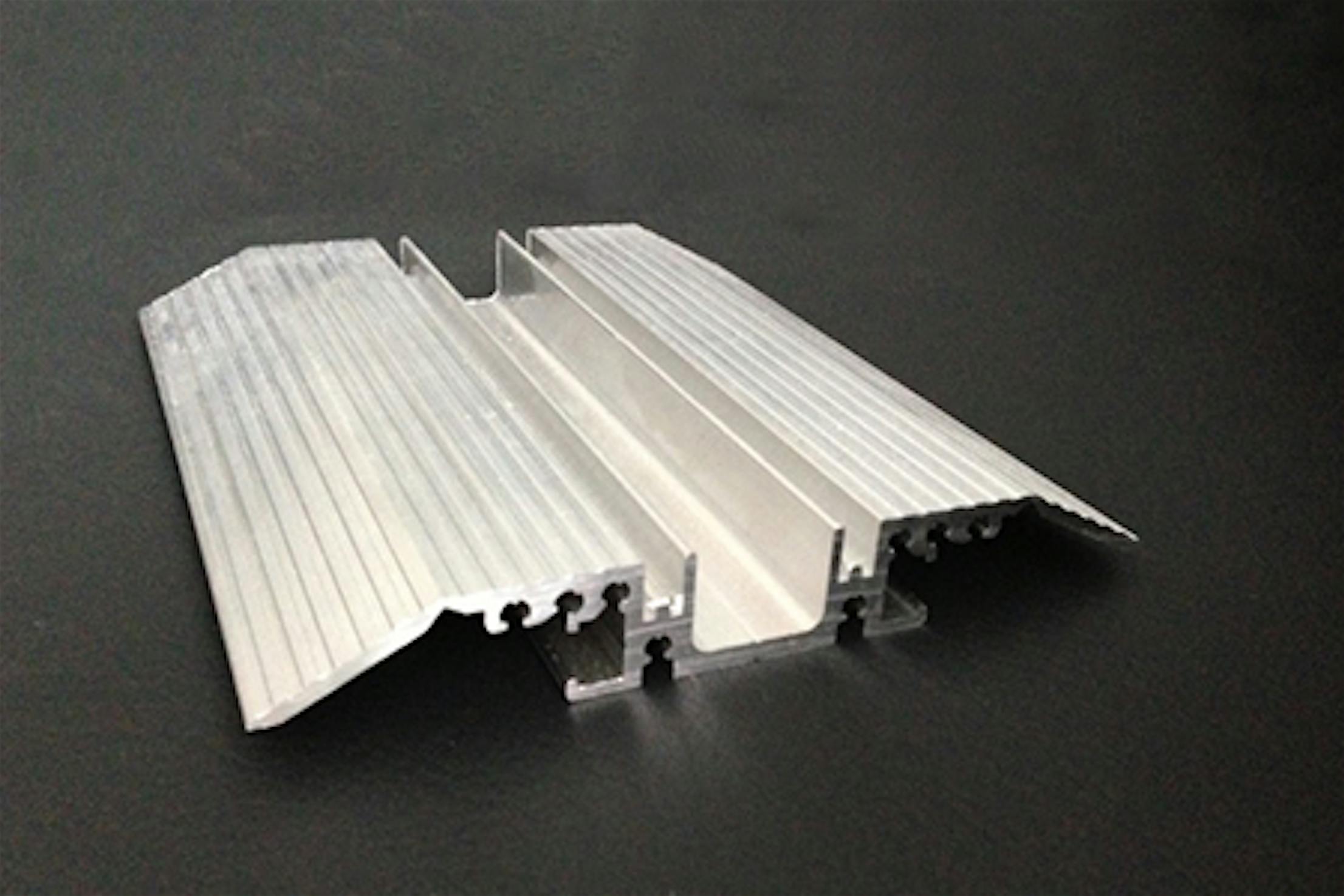

SL70 has five sill options: High Performance (Raised), Low Profile Saddle, Low Profile Saddle with UniverSILL®, Flush, and Surface Mounted.

See Sill Options

Units can be supplied either glazed with 15/16 (24 mm) clear insulating tempered or insulating Low-E tempered glass or other high performing safety glass such as Heat Mirror, Triple Glazed, acoustic, special tint, etc., or other glass on request.

See Glazing Options

Stylish Handles in Multiple Finishes

Our handles are both functional and stylish and can be customized to accentuate your space and reflect your style.

See Handle Options

Locking for Maximum Security

Standard to the system is concealed locking between folding panels that operates with a 180° turn of a flat handle.

See Locking Options

Retractable Screens

A retractable screen add-on is perfect for blocking bugs while providing privacy and fresh air. Screens are not available through NanaWall Systems.

Retractable Screens

Over 90 standard configurations for straight forward folding systems.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More ConfigurationsCurvaceous configurations can be created using our single track, bi-folding, frameless, and framed products. We highly encourage their use in your residential or commercial designs.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

All standard configurations are available in cornerless options.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

Combine a NanaWall Folding Windows with a NanaWall Folding Glass Wall seamlessly

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More ConfigurationsWe consider ourselves your partners from day one. Connect immediately with a NanaWall expert to answer your questions and explore how we can support your project.

(866) 210-4285

Monday - Friday: 7 AM - 5 PM PST