HSW75

Transparent Aesthetics Limitless Flexibility

- Customizable stacking

- Unlimited spans

- Standard sizes up to 4' 1" (1250 mm) in width and 10' 6" (3200 mm) in height for sliding panels

Single Track Offers Total Customization

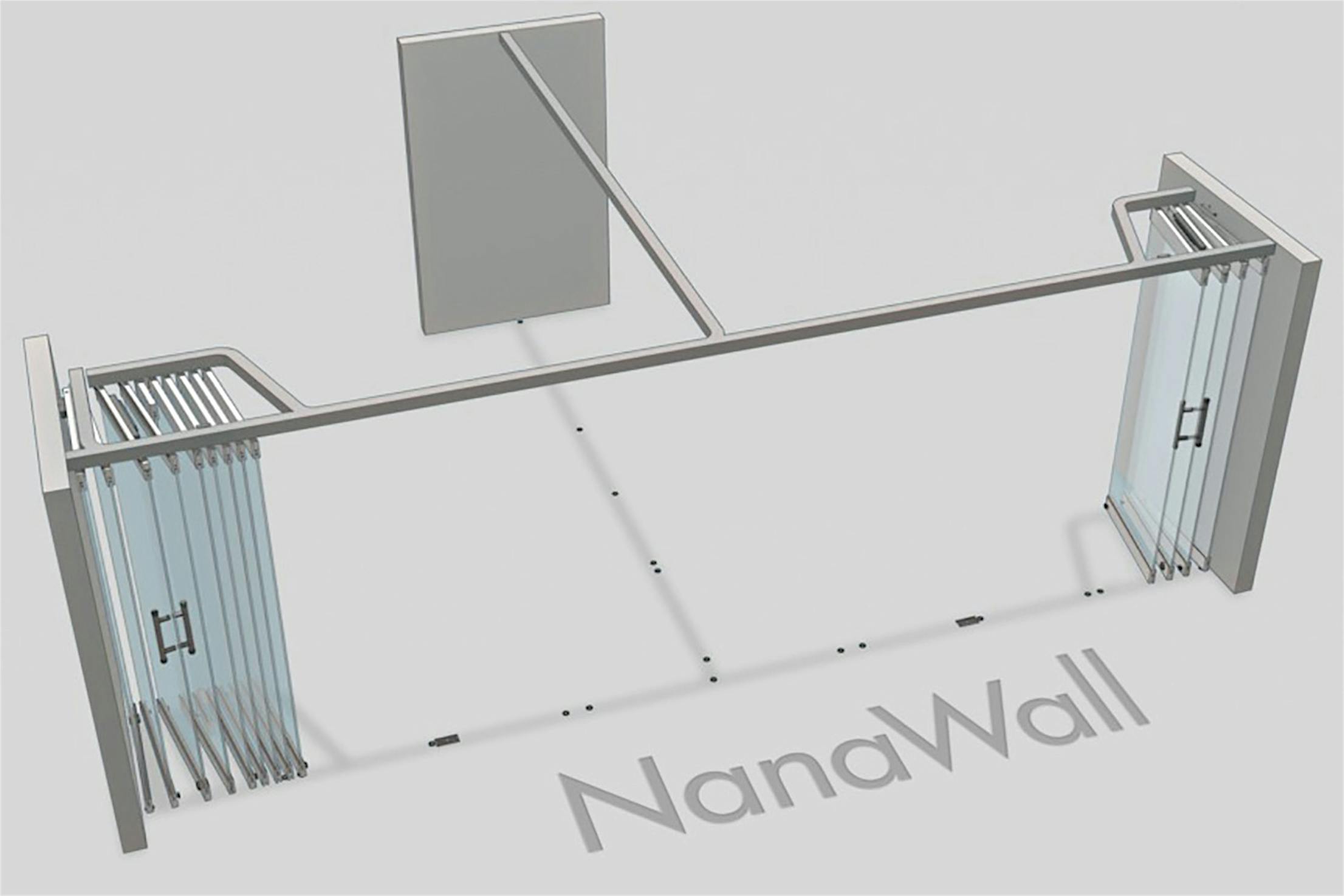

Create an unlimited span of top-hung panels which are able to easily navigate with single handed operation through multiple angle changes from 90° to 180°. Optimize space management or to solve unique design challenges, stacking options and minimal parking bays can be designed with total customization.

Unlimited Spans, Customizable Stacking

A unique combination of aesthetics, flexibility, and ingenuity make the HSW75 our most advanced frameless glass door ever

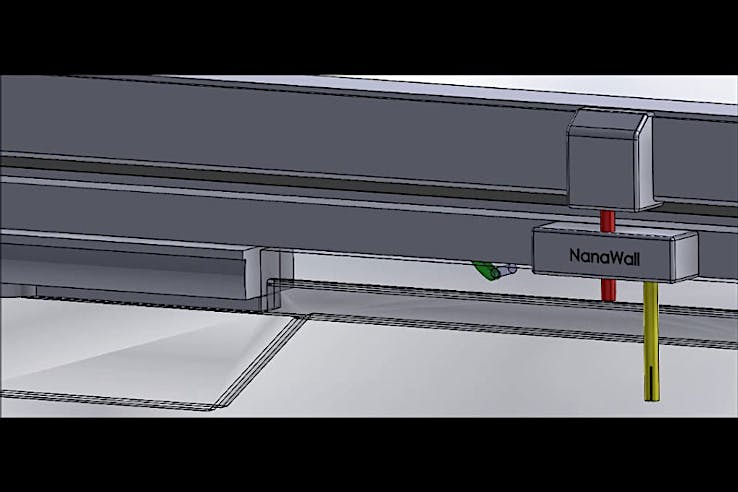

3 15/16" continuous rail for outstanding aesthetics

The HSW75 system comes standard with a 3 15/16" (100 mm) continuous top and bottom horizontal rail –even on single action sliding panels– allowing for a beautiful aesthetic and maximum glass. Customized rail options are available in increments of 3/16" (5 mm) from 5 1/4" (133 mm) to 7 13/16" (198 mm). To meet ADA requirements, two options are offered: a 10" (254 mm) bottom rail or a 4 3/4" (120 mm) chamfer bottom rail.

Standard HSW75 comes in sizes up to 4' 1" (1250 mm) in width and 10' 6" (3200 mm) in height for sliding panels. For all single/double action sliding panels, sizes available are up to 3' 3" (1000 mm) in width and 10' 6" (3200 mm) in height. For single/double action end panels (non-sliding), sizes available are up to 3' 7" (1100 mm) in width and 10' 6" (3200 mm) in height.

View Panel Sizing Chart

The single track sliding all glass wall offers the option of selective panels that convert from sliding to pivoting for convenient swinging entrance/egress doors almost anywhere within the span of the opening in order to meet your traffic pattern requirements. Pivot panels are available as either single action or double action sliding panels. A pair of either single or double action swing panels can be added to function similarly to French doors.

End panels (non-sliding) can be single/double action panels with pivot points or single/double action panels with offset hinges that are capable of opening 180°.

A locking ladder pull integrates a locking mechanism with a profile cylinder at hand height into the tubular designed handle eliminating the need to kneel to lock the door at the bottom rail. The locking ladder pull comes in a brushed stainless steel finish.

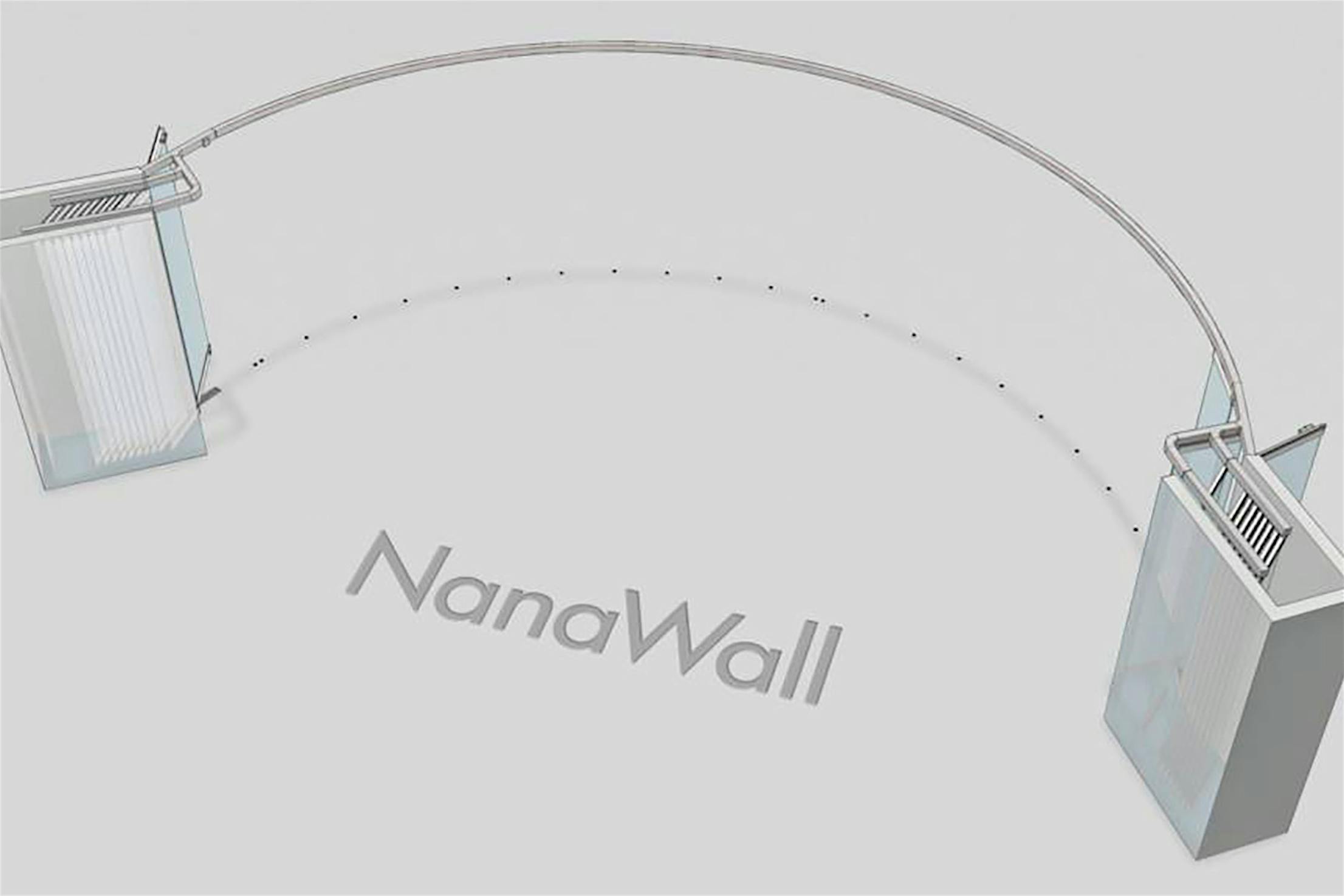

With the HSW75, to meet the needs of specific designs and to improve smooth operation, a true curved radius track, composed of an engineered single piece of metal, is available for gentle angle changes and ease of installation.

Intelligent Roller For Single Handed Operation

The unique "intelligent" rollers and guide technology ensure for easy, trouble-free, single-hand operation. The rollers are designed using hardened steel ball bearings with glass fiber reinforced polyamide wheels with memory effect and polyamide bumpers for quiet and smooth operation.

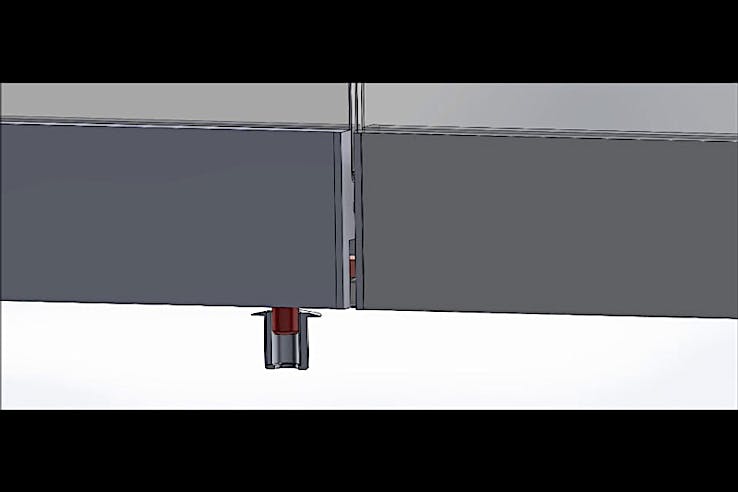

Patented Self-activated Automatic Panel to Panel Interlock

For straight units, the automatic floor bolt is self-activated by simply moving the panels on to one another. Once the first panel is positioned, the following panel activates the wheel and ramp assembly to automatically release the floor bolt effectively locking the panel into place without the need to lock it manually. No kneeling is required.

Patented Release System Converting Single/double Action Sliding Panels to Pivot and Vice Versa

The HSW75 has a patented release system which combines the fixing and locking mechanism for single/double action stacking doors. This patent improves the handling of turning the single/double action door into a sliding panel in a 2-step rather than a 3-step process.

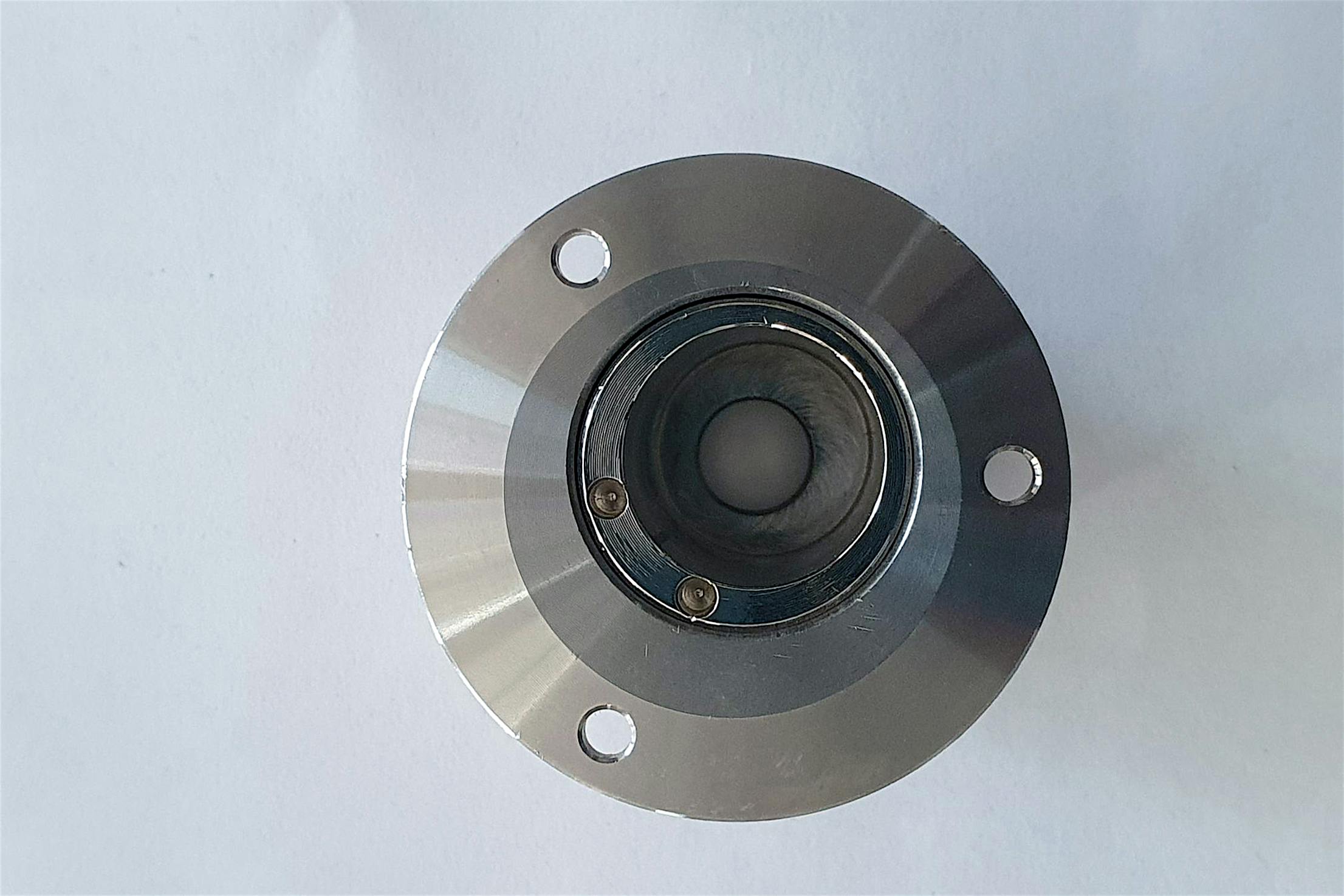

Adjustable Floor Sockets

Standard to the HSW75 are eccentric floor sockets. The built-in adjustability helps to deal with tolerances and building settlements.

Ease of Operation

NanaWall systems offer single-handed operation and move smoothly with little effort

Flexible Configurations

Design with no limits – our glass walls can be tailored to your imagination.

Interior Ready

Sill options designed specifically for interior applications.

Sustainable Design

NanaWall products contribute to multiple LEED rating systems and potentially several credit categories.

Test Results

Single/double action panels with pivot points have passed 500,000 cycle testing.

Structural Load Deflection, Forced Entry, and Cycle Testing Results

Continued Long-Term Satisfactory Operation

Smooth sliding and folding operations are assured even when dirt or debris might collect in the bottom track. State-of the-art hardware is used with patented, sealed, ball bearing running carriages. Compensation and adjustment features provide long-term ease of operation.

What Our Customers Have to Say

SK&A Office - Case Study

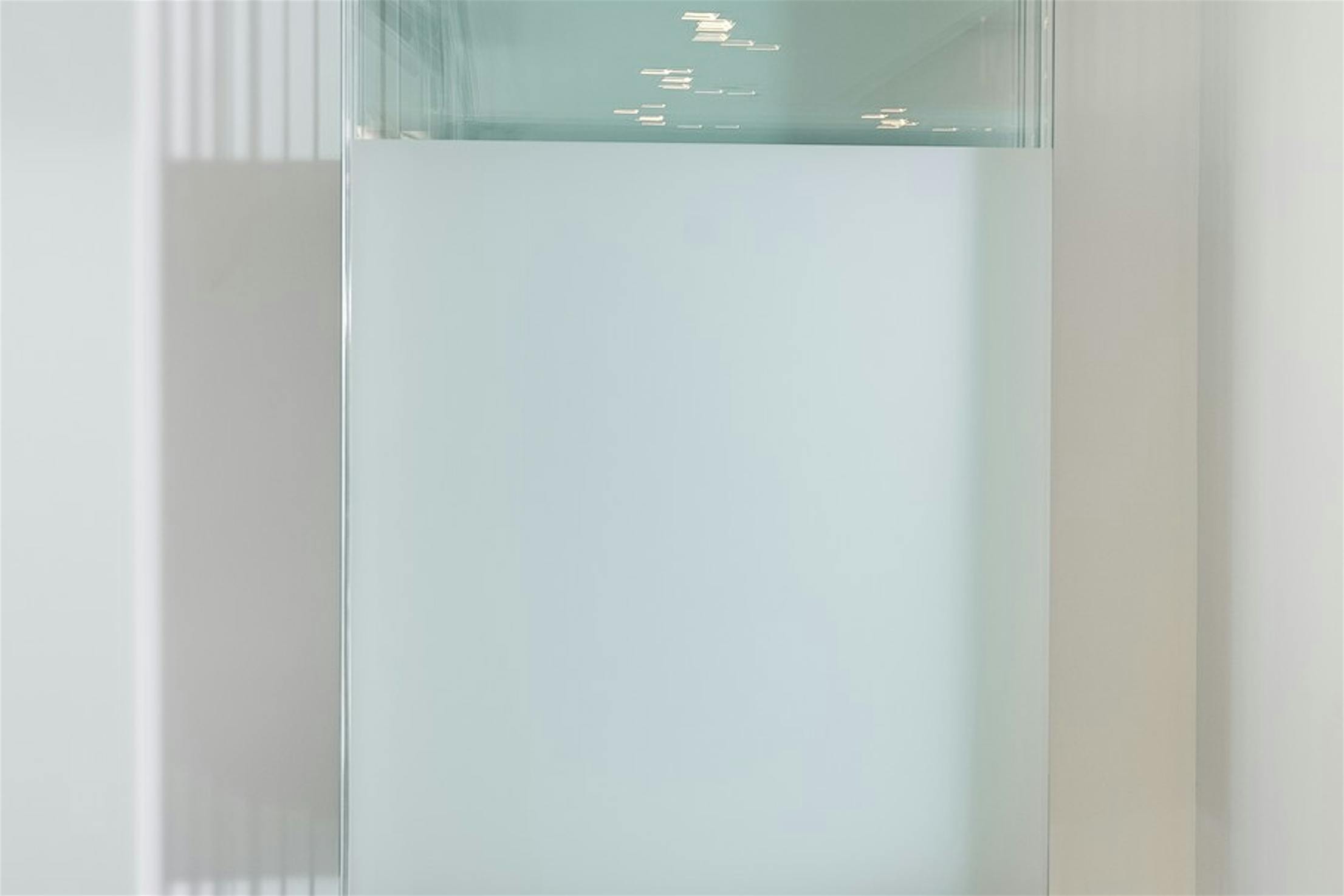

This office leveraged existing elevator lobby space to create a flexible, versatile public-facing conference room using a frameless opening glass door.

Dairy Farmers of America - Case Study

By designing the conference room with PrivaSEE, this office achieved a space with a high degree of acoustic privacy, while maintaining a sense of openness.

"The nicest meeting room we have in this building is the [PrivaSEE] boardroom."

— Architect

Quick release floor bolt with spring loaded security feature, floor bolt with profile cylinder, TUBO 100

See Locking Options

Our handles are both functional and stylish and can be customized to accentuate your space and reflect your style.

See Handles Options

Standard glass is reduced iron with a thickness of 1/2" (12 mm) for tempered and (12.52 mm) for laminated.

Additional glazing options include low iron and decorative glass. An optional white interlayer can be added for the closed panels to be used similarly to a white board. Please contact NanaWall Systems for more details.

To lower glass stress, glass is clamp installed for equal distribution of weight.

See Glazing Options

HSW75 options : Adjustable Floor Sockets.

See Sill Options

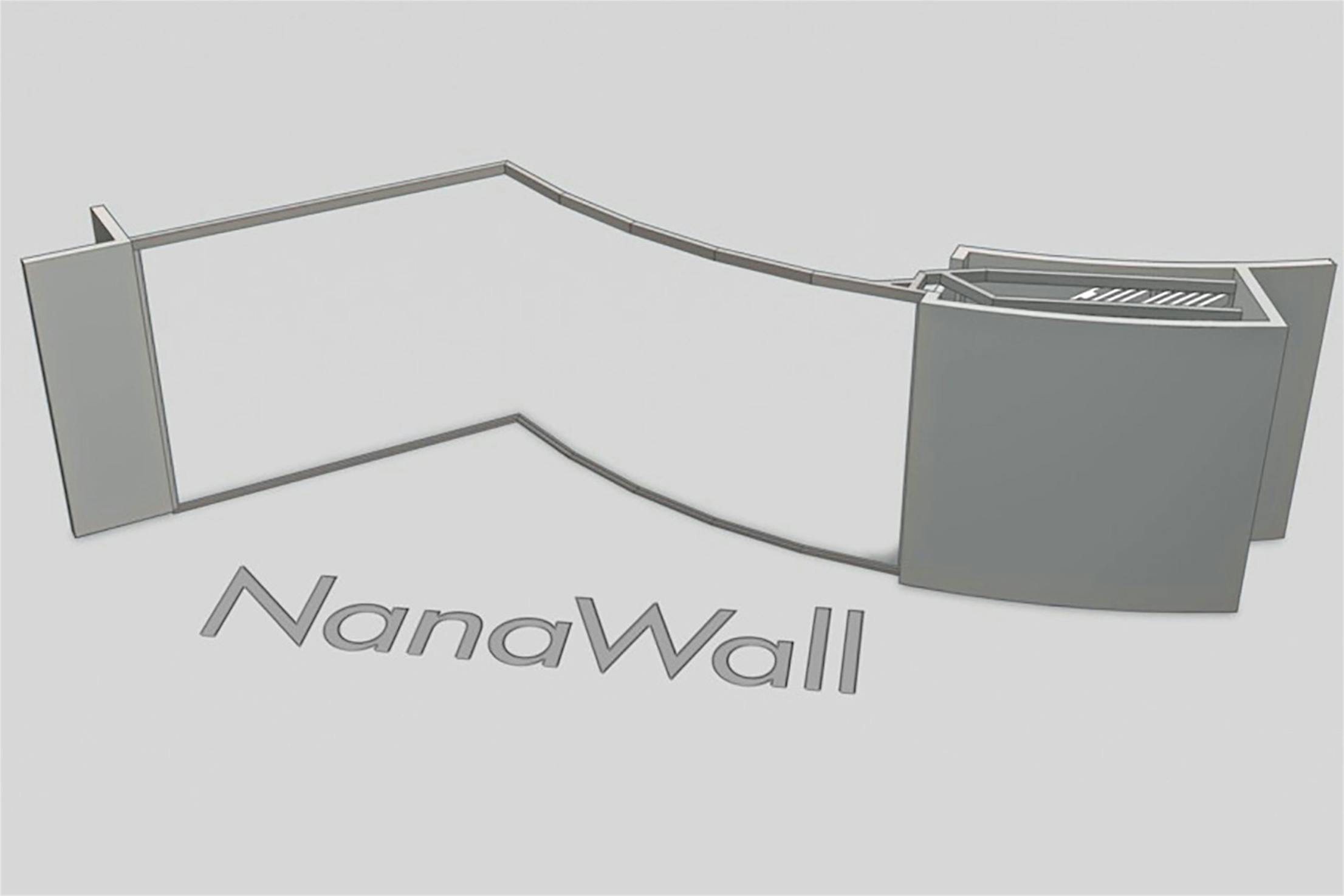

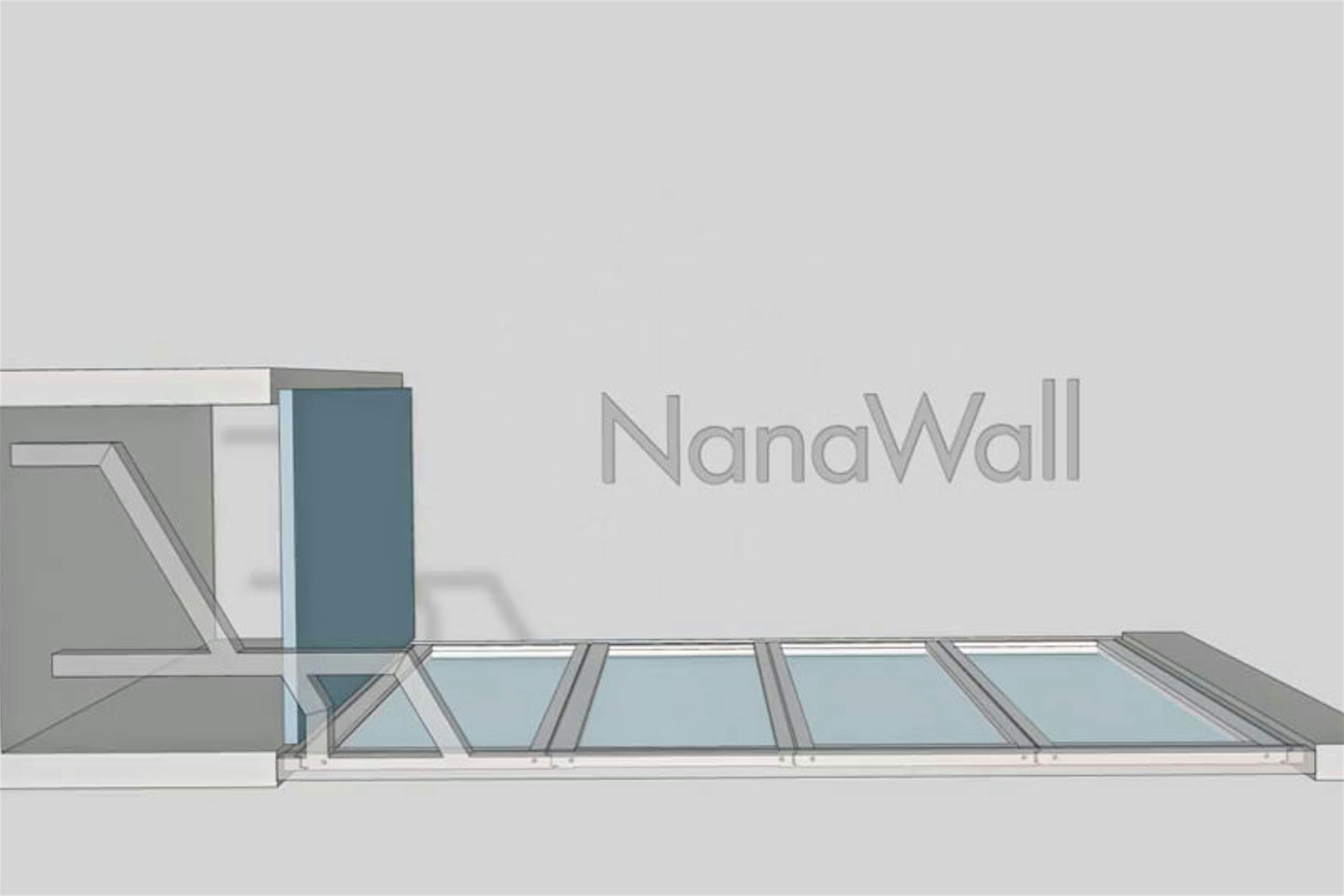

Basic stacking concepts.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More ConfigurationsRemoteSTACK is a fairly unique feature that allows the individual panels of a single track stacking glass door to park well outside the opening. RemoteSTACK not only facilitates pure openings but allows panels to park virtually anywhere.

Contact our dedicated design team for more possibilities.

More ConfigurationsCurvaceous configurations can be created using our single track, bi-folding, frameless, and framed products. We highly encourage their use in your residential or commercial designs.

Contact our dedicated design team for more possibilities.

More ConfigurationsExplore limitless possibilities with our systems. Contact our dedicated design team for more possibilities.

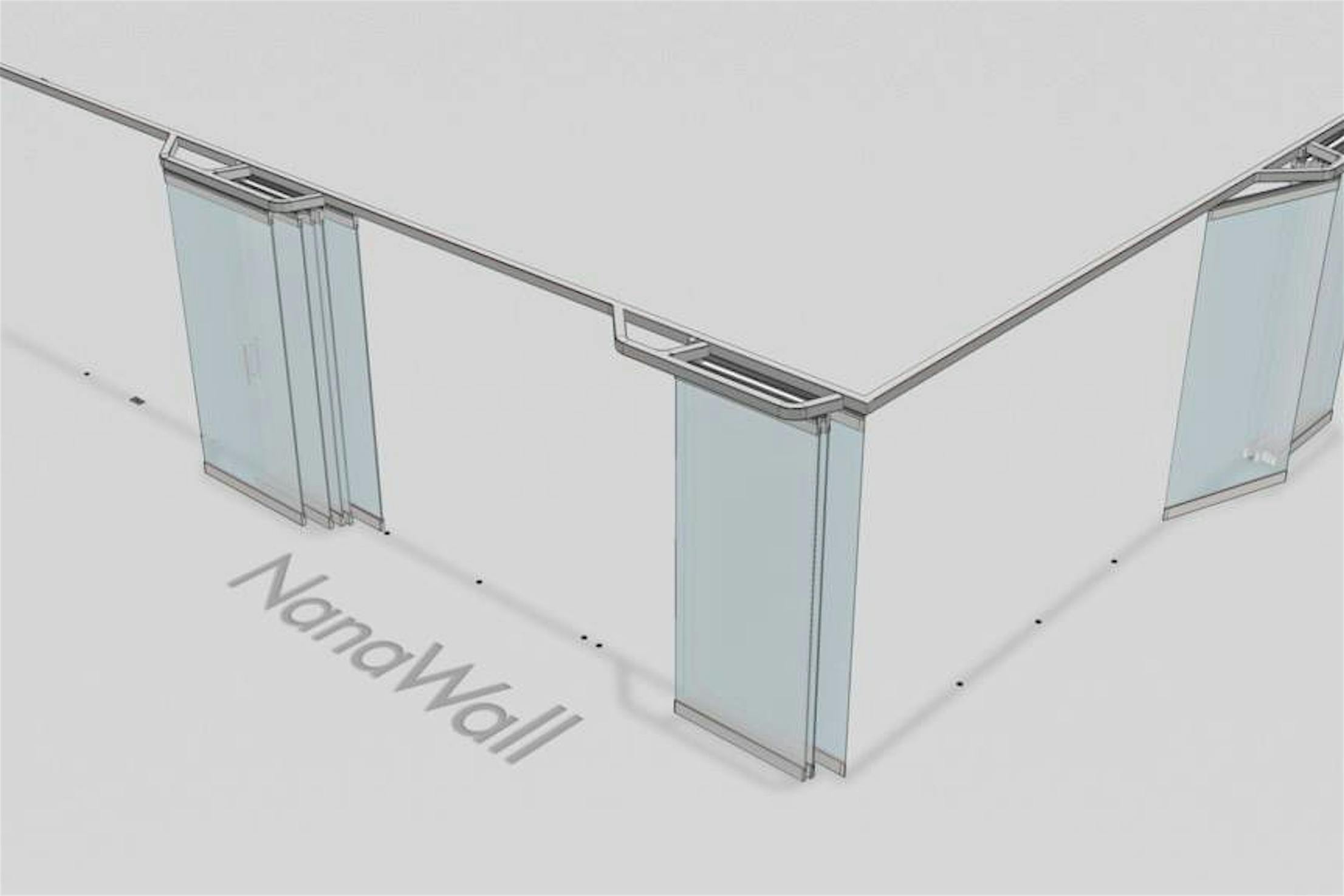

More ConfigurationsAll standard configurations are available in open corner options.

Explore limitless possibilities with our systems. Contact our dedicated design team for more possibilities.

More Configurations

Stack panels out of site, example of enclosed stacking area by others

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

For every type of space, there is a NanaWall. With more than 20 glass wall systems and endless hardware and configuration options, our products can accommodate most any type of space, indoors or out.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

See What's Possible with NanaWallWe consider ourselves your partners from day one. Connect immediately with a NanaWall expert to answer your questions and explore how we can support your project.

(866) 210-4285

Monday - Friday: 7 AM - 5 PM PST