SL45

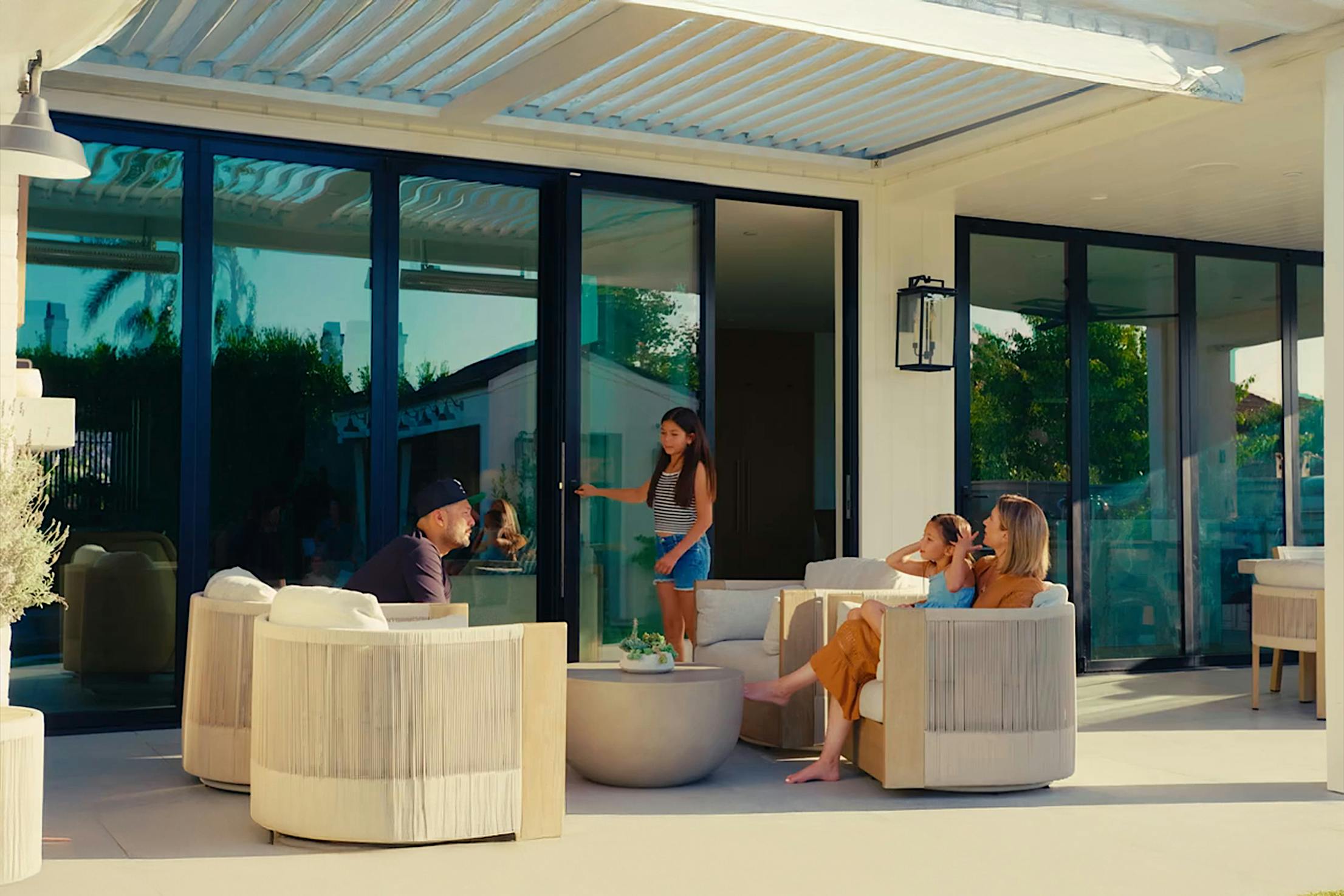

Aluminum Framed Folding Glass Door Designed to Solve Specific Architectural Challenges

- Acoustically tested to meet up to unit STC 34 with sill options designed specifically for interior applications

- Can be configured with segmented curves and 90° - 135° open corners

- Panels can fold 180° and stack parallel to the opening against the wall

Segmented Curve Capabilities

A key feature is the ability to create a segmented curve utilizing the flat glass panels to achieve a curved aesthetic. Segmented curves of 6° - 12° can be created with or without an integrated swing door and 90° - 135° open corner configurations.

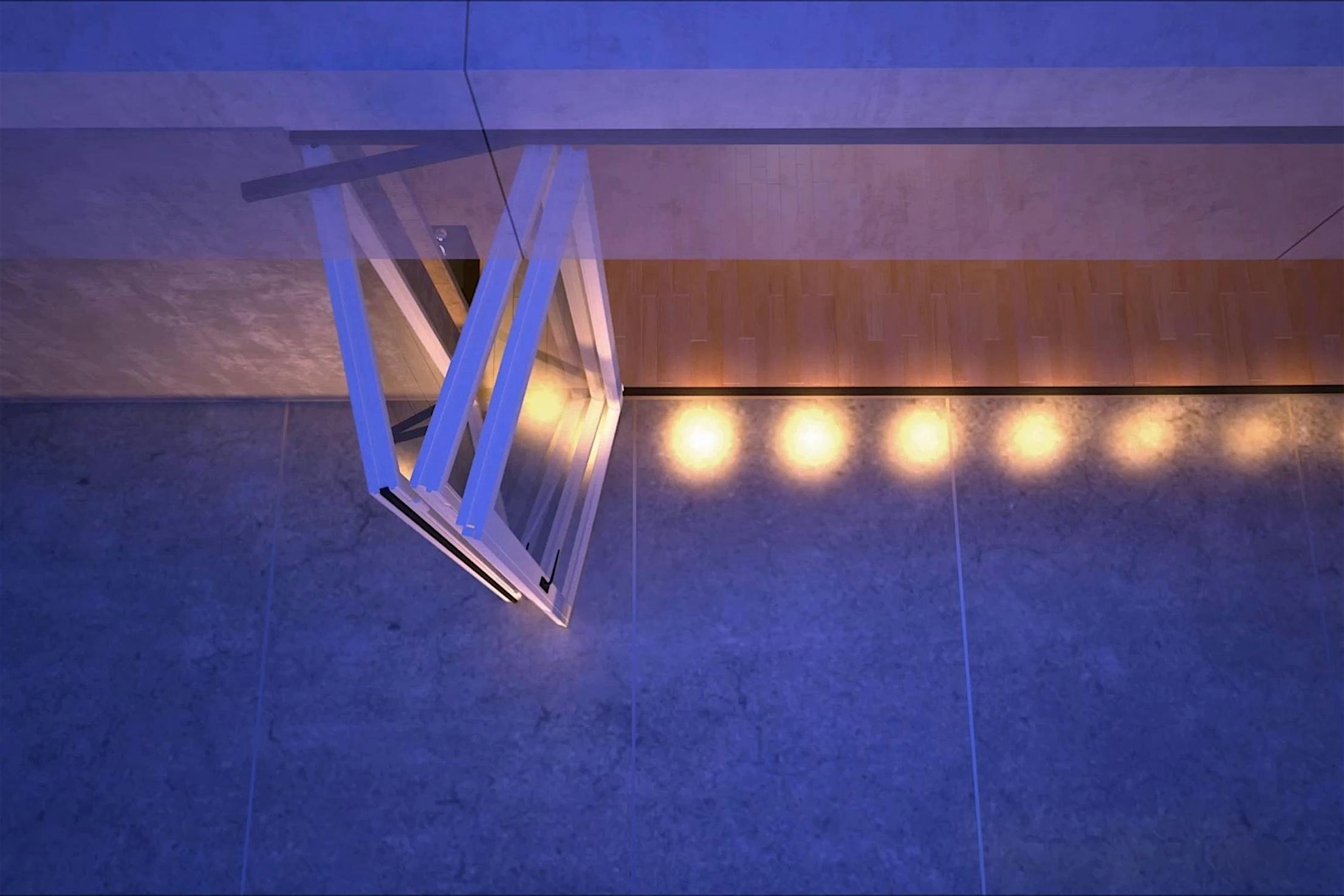

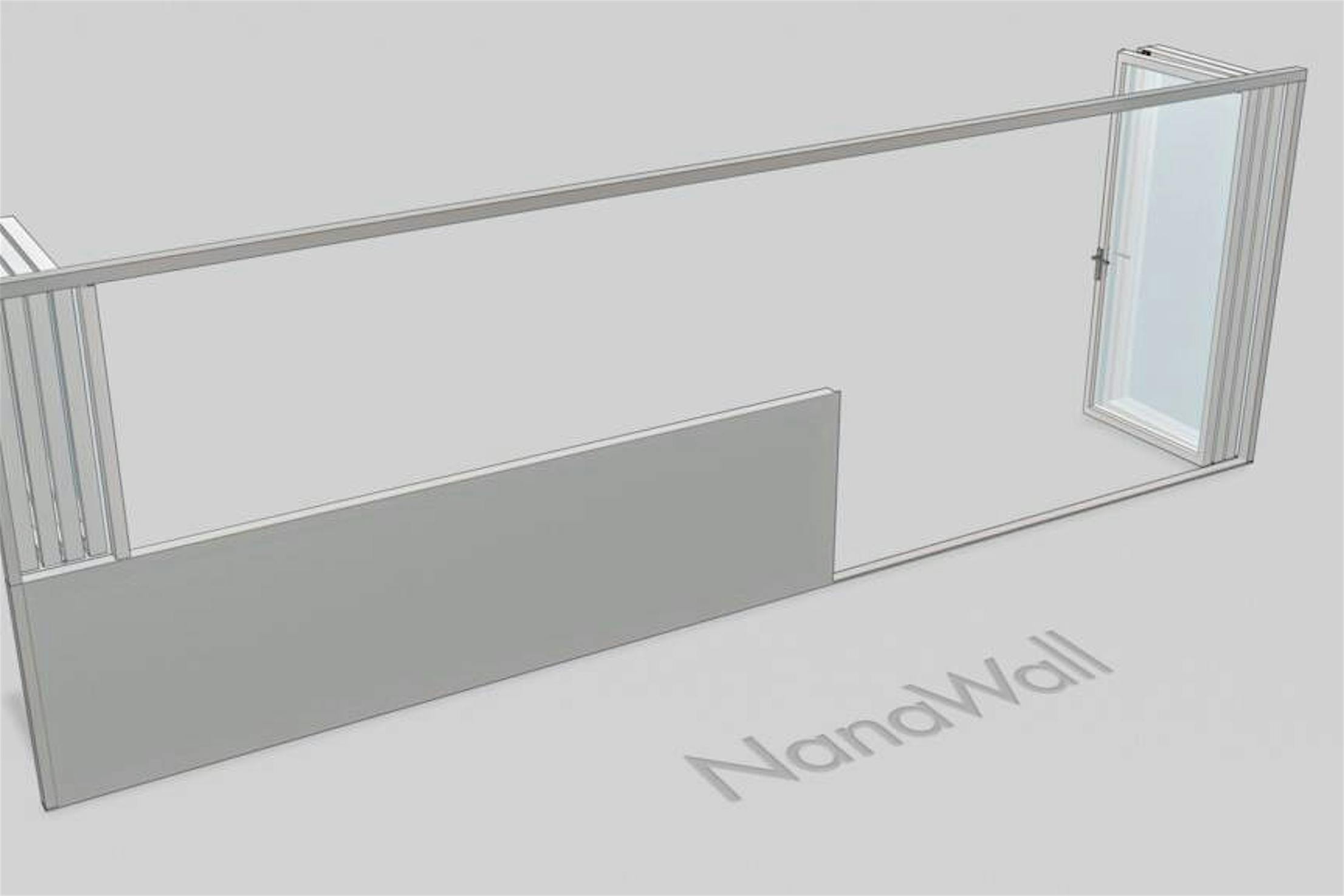

Stacks Flat Against the Wall

FoldFlat is a unique configuration of the SL45 that allows the panels to fold 180° and stack flat up against the outside wall, removing the panels from obstructing walkways while also maximizing the circle of sight.

Inward and Outward Stacking, Same Opening

The SL45 includes the ability to have each panel stack open opposite each other within the same plane of the opening (inward and outward) on the same single track.

Innovative design enables the folding panels to stack 180° flat up against the wall for maximum outside space usage and greater circle of sight from the inside.

See FoldFlat Product Detail

- Unhinged Paired Panels

- Segmented Curve Capabilities

- FoldFlat - Panels Stack Flat Against Wall

- Inward and Outward Stacking, Same Opening

- Dual Height Window Door Combo

- Cornerless

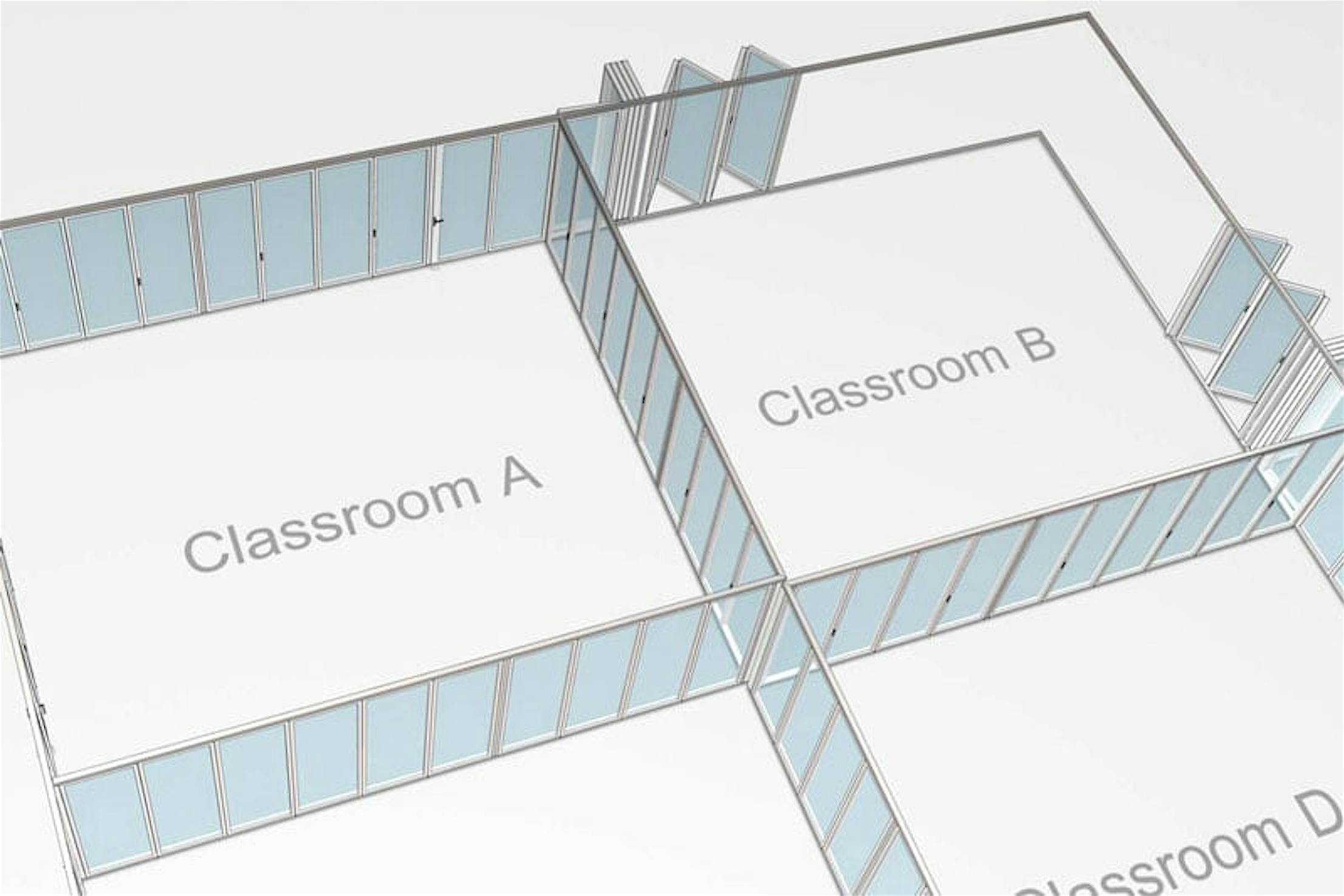

NanaWall SL45 offer flexibility, natural daylight and visibility in interior school application. Classrooms turn into adaptable multi-functional spaces and when closed, the SL45 provides acoustical buffering for privacy.

Unlike traditional glass wall partitions, the SL45 provides transparency but also the flexibility and sound control needed for workplace interiors.The sound-rated SL45 has been acoustically tested to meet up to unit STC 34 with operable capabilities.

SL45 Acoustical Performance

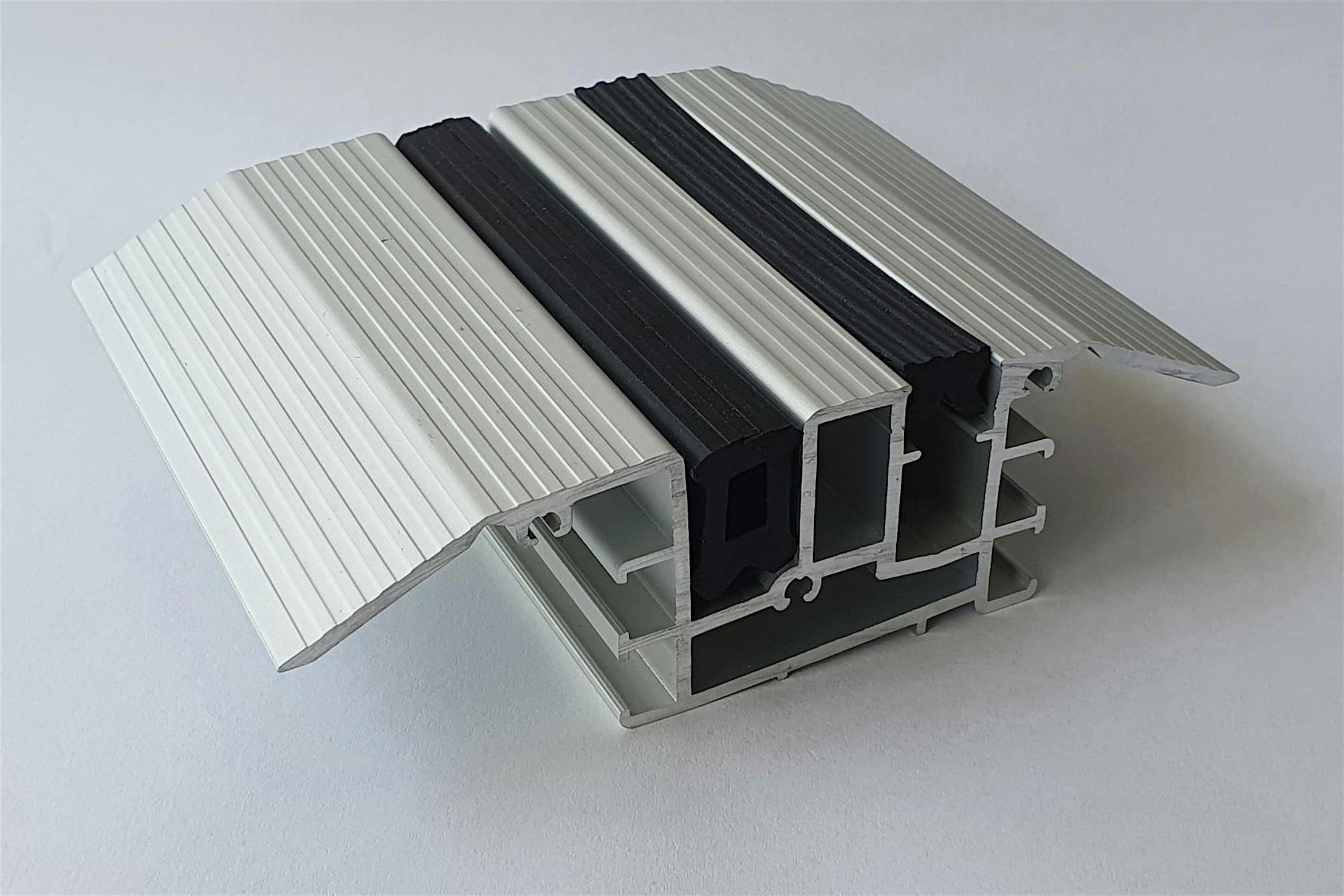

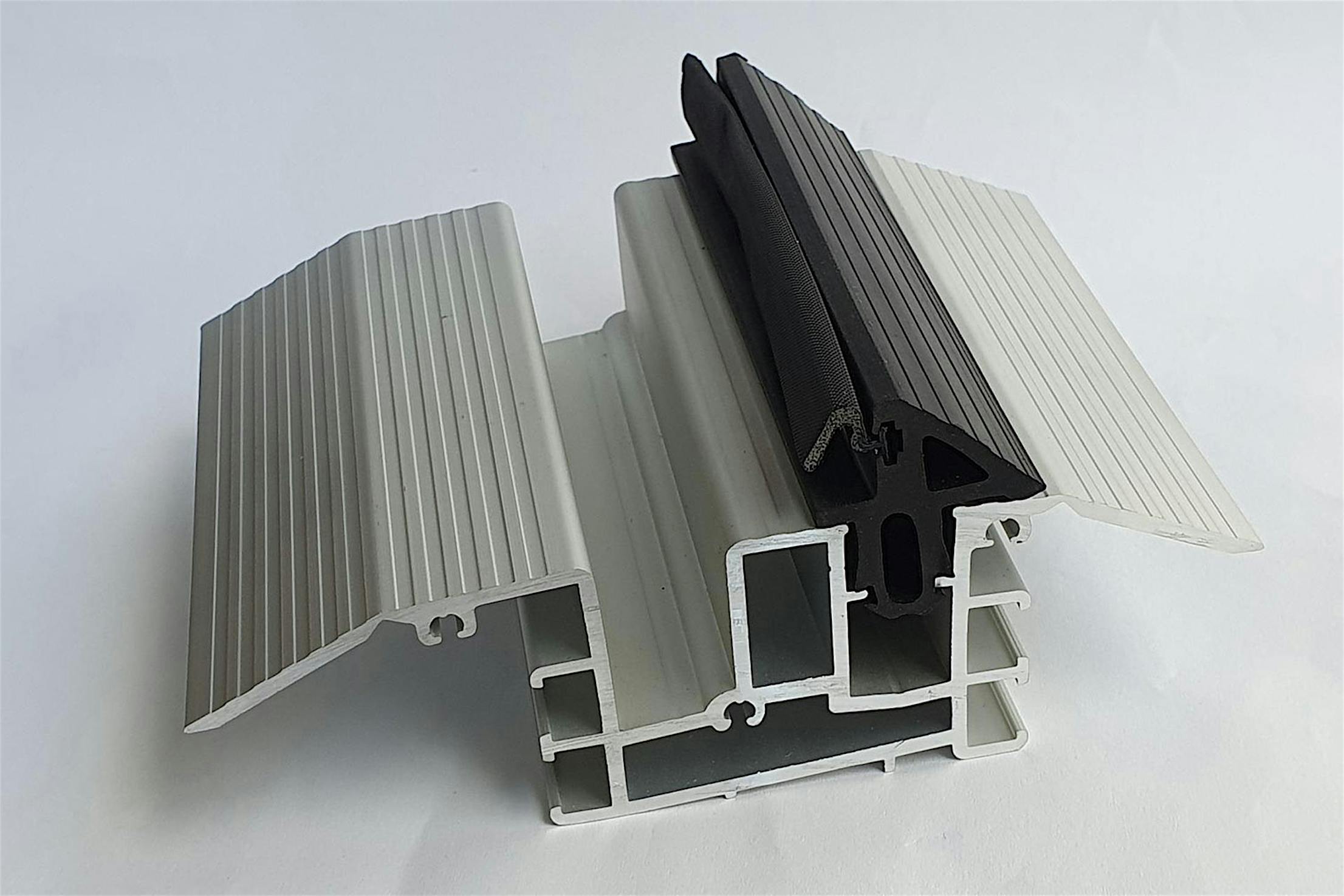

All Aluminum, Narrow Sightlines

The NanaWall SL45 features an all-aluminum design for low maintenance finishes and minimal sightlines that form a picture frame like appearance. All folding and locking hardware is integrated into the profiles for a clean look. There are no surface mounted hinges.

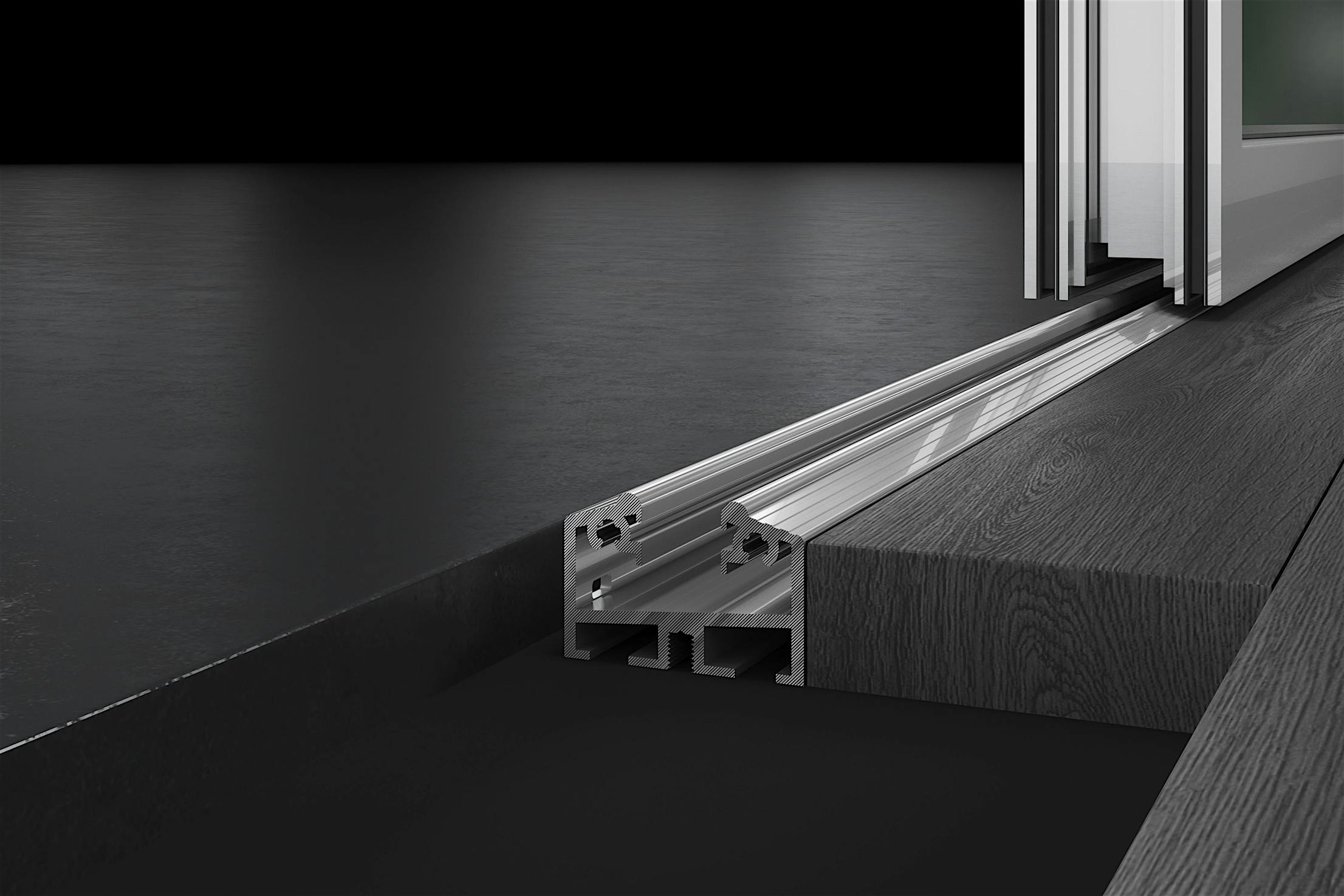

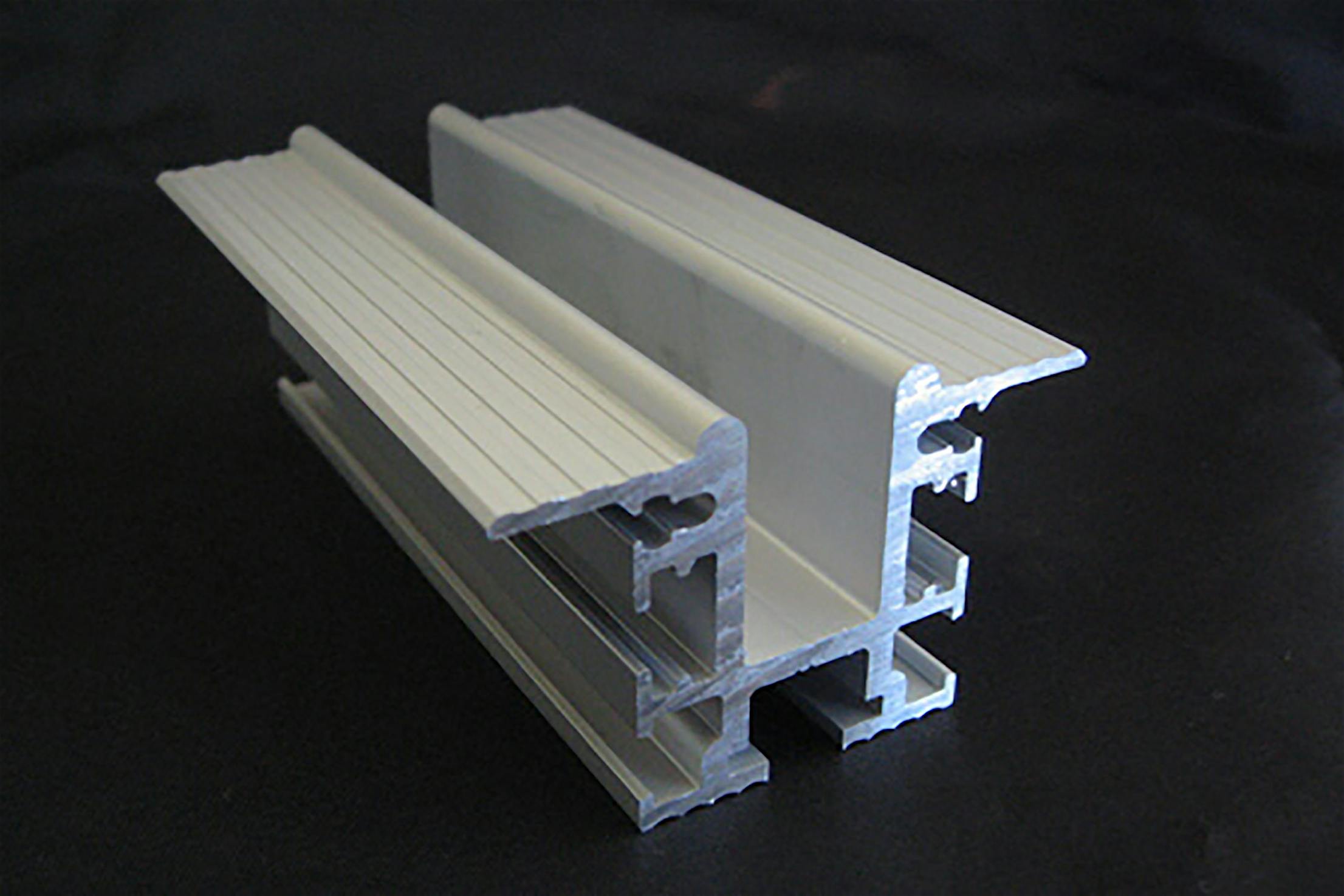

Sill Options

The SL45 offers four sill options to meet application requirements including the Standard Sill, Low Profile Saddle Sill, Flush Sill, and the Surface Mounted Sill.

Commercially Rated Swing Door

The SL45 swing panel has been engineered for commercial traffic and has been independently tested to five hundred thousand opening and closing cycles.

Interior Ready

Acoustically tested to meet up to unit STC 34 and sill options designed specifically for interior applications.

Ease of Operation

The epitome of strength and durability with the ease of single-handed operation.

Independently Tested

Tested for air and water penetration resistance, structural deflection, and forced entry.

Sustainable Design

This product contributes to multiple LEED rating systems and has HPD certification.

Download Declaration Documents

Test Results

NanaWall SL45 has been independently tested for air and water penetration resistance, structural deflection, and forced entry. Also with NFRC rated, certified and labeled thermal performance.

Florida Product Approval # FL37258

See Air, Water, Structural, Thermal, and Forced Entry Results

Sound Rating Up to Unit STC 34

NanaWall SL45 has been tested at an accredited and certified independent laboratory. We test our product to meet the highest standards of ASTM E90, ISO 10140-1, 2, 4, 5. STC calculations meets standards of ASTM E413, and ISO 717-1.

Acoustical Performance ResultsWhat Our Customers Have to Say

CompTIA Office

With "order and light" as the watchwords of the renovation project of the interior of CompTIA, KUBE set about finding ways to create a feeling of openness, while also providing privacy through sound attenuation.

Burleson Elementary

To optimize the limited floor space and increase the classroom flexibility at Burleson Elementary, two NanaWall SL45 systems replaced fixed walls to create a new multipurpose FlexSpace.

“This flexibility allows teachers to gain access to shared resources and adapt space for small and large groups as well as project-based learning activities.”

— Stuart Brodsky, Architect

50 standard colors that come at no additional cost, with an additional 200+ colors to choose from.

See Finish Options

The SL45 offers four sill options including the Standard Sill, Low Profile Saddle Sill, Flush Sill, and the Surface Mounted Sill.

See Sill Options

Units can be supplied either glazed with 15/16 (24 mm) clear insulating tempered or insulating Low-E tempered glass or other high performing safety glass such as Heat Mirror, Triple Glazed, acoustic, special tint, etc., or other glass on request.

See Glazing Options

Stylish Handles in Multiple Finishes

Our handles are both functional and stylish and can be customized to accentuate your space and reflect your style.

See Handle Options

Locking for Maximum Security

Standard to the system is concealed locking between folding panels that operates with a 180° turn of a flat handle.

See Locking Options

Retractable Screens

A retractable screen add-on is perfect for blocking bugs while providing privacy and fresh air. Screens are not available through NanaWall Systems.

Retractable Screens

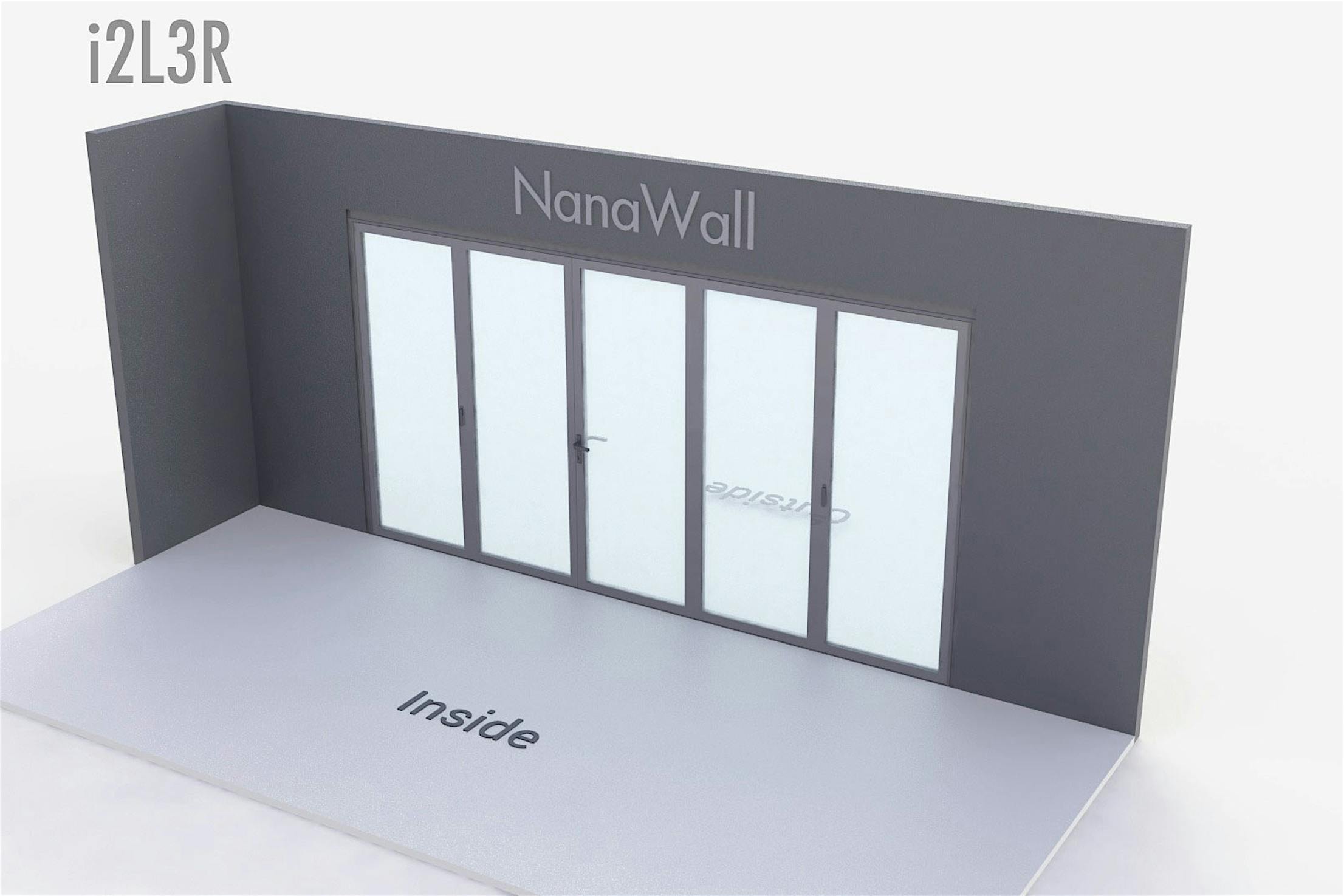

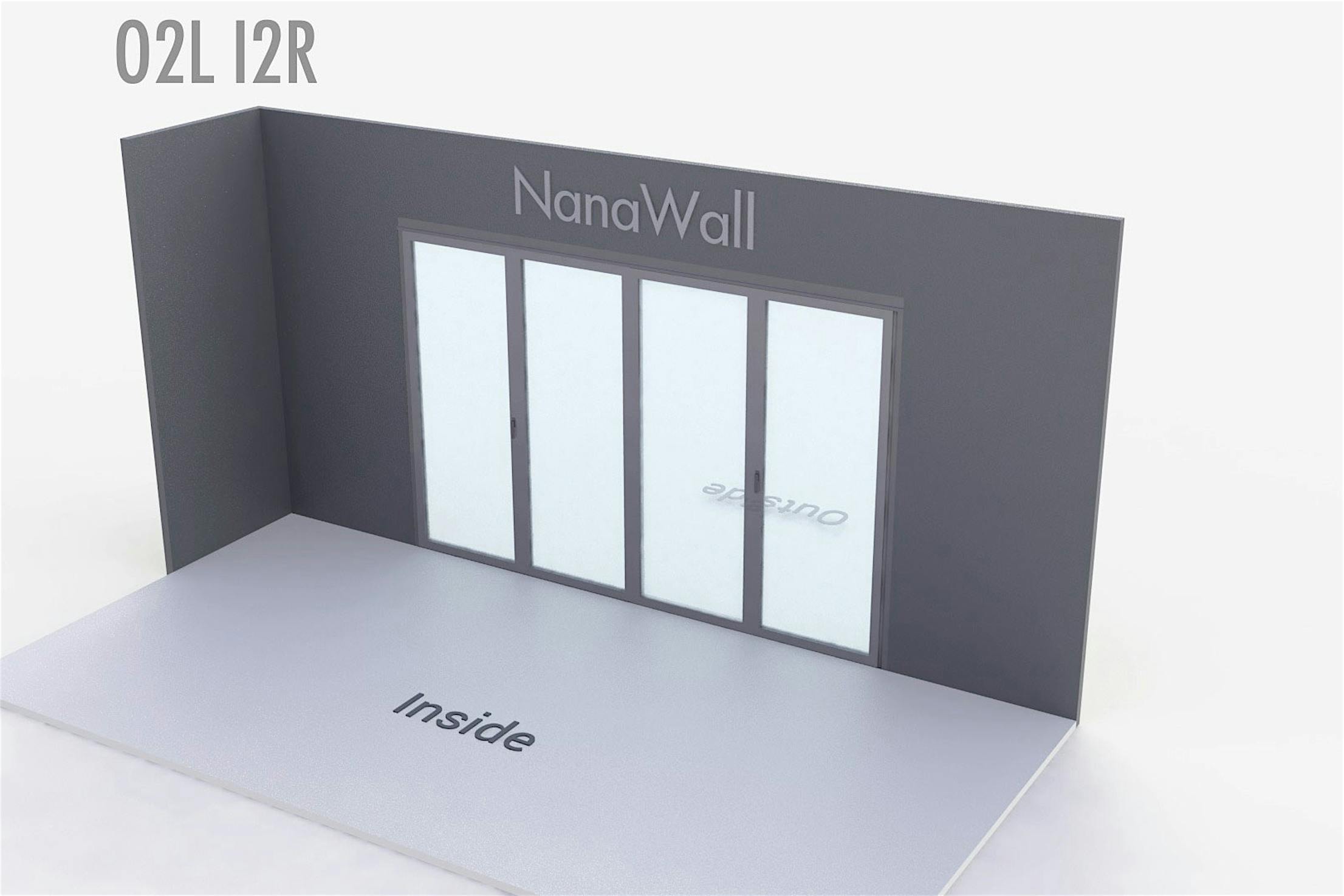

Over 90 standard configurations for straight forward folding systems.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

Taking Accordion Glass Doors Beyond Traditional 90-degree Stacking.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

FourFold Panel Sets are able to move and stack either to the right, left, or center within the same track allowing the panels to be stacked in the most convenient location as needed.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

Curvaceous configurations can be created using our single track, bi-folding, frameless, and framed products. We highly encourage their use in your residential or commercial designs.

Contact our dedicated design team for more possibilities.

More Configurations

Explore limitless possibilities with our systems. Contact our dedicated design team for more possibilities.

More Configurations

All standard configurations are available in open corner options.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More Configurations

Combine a NanaWall Folding Windows with a NanaWall Folding Glass Wall seamlessly

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More ConfigurationsWe consider ourselves your partners from day one. Connect immediately with a NanaWall expert to answer your questions and explore how we can support your project.

(866) 210-4285

Monday - Friday: 7 AM - 5 PM PST