SL73 Hurricane

Hurricane Resistant Folding Glass Door

- Florida Product Approved with Impact Glass in High Velocity Hurricane Zone (HVHZ)

- Forced entry rated and dynamic water performance

- Eliminates the need for unsightly hurricane shutters

Completely Impact Rated

Many approved systems are limited to outward opening and are not approved for areas that need protection from water. The NanaWall SL73 offers a complete impact rated system, allowing both inward and outward opening systems to qualify, while also providing protection from water penetration.

Our Toughest Folding System

The NanaWall SL73 is perfect for securing common areas and in areas exposed to heavy rain. Both forced entry rated and passing a more difficult water test, you can rely on the NanaWall SL73 when you need it most.

Reinforced for Mid-Rises

The NanaWall SL73 has achieved design pressure performance making it acceptable for up to mid-rise level exposures.

Many approved systems are limited to outward opening and are not approved for areas that need protection from water. The NanaWall SL73 offers a complete impact rated system, allowing both inward and outward opening systems to qualify, while also providing protection from water penetration.

See Florida Approved NanaWall Systems

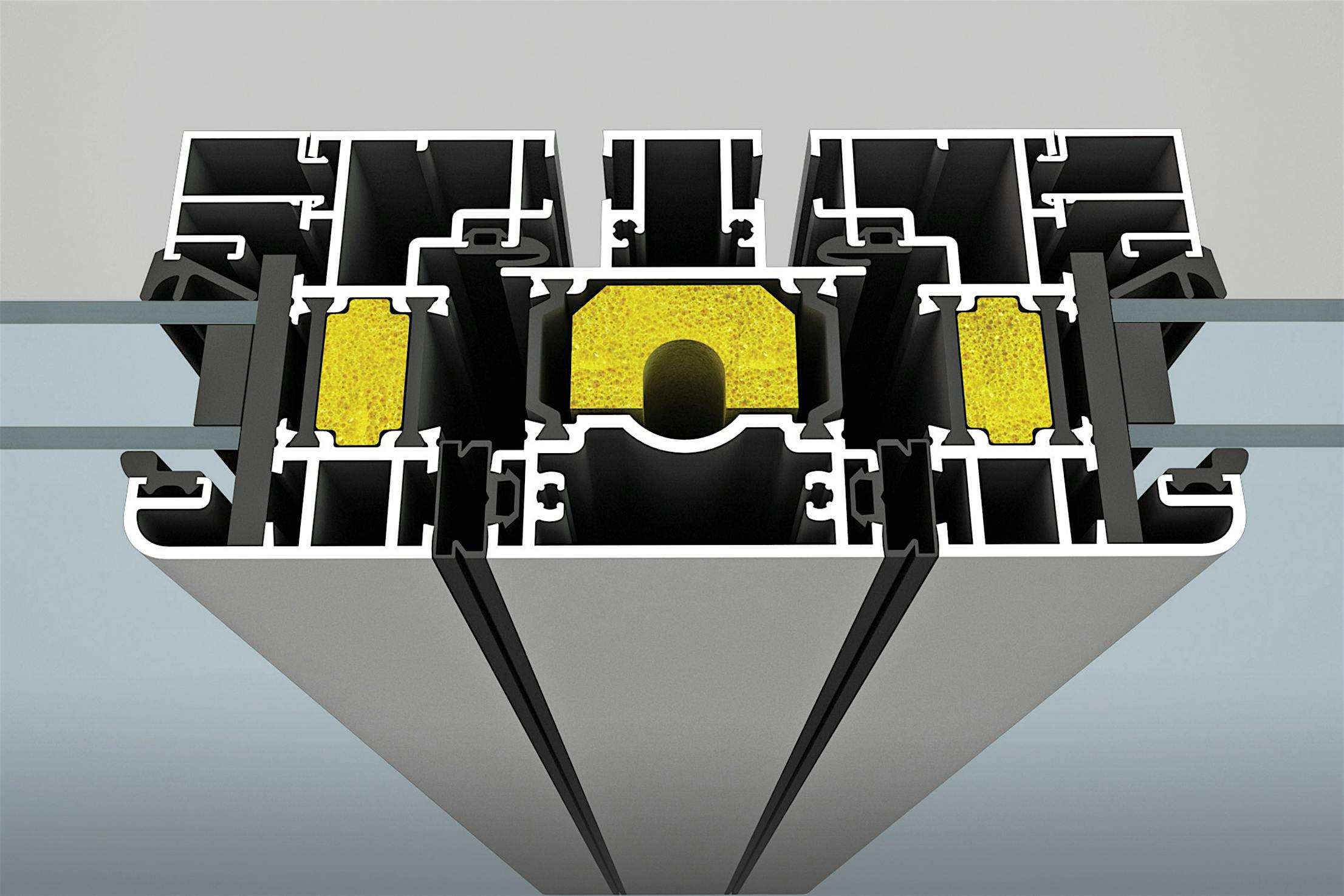

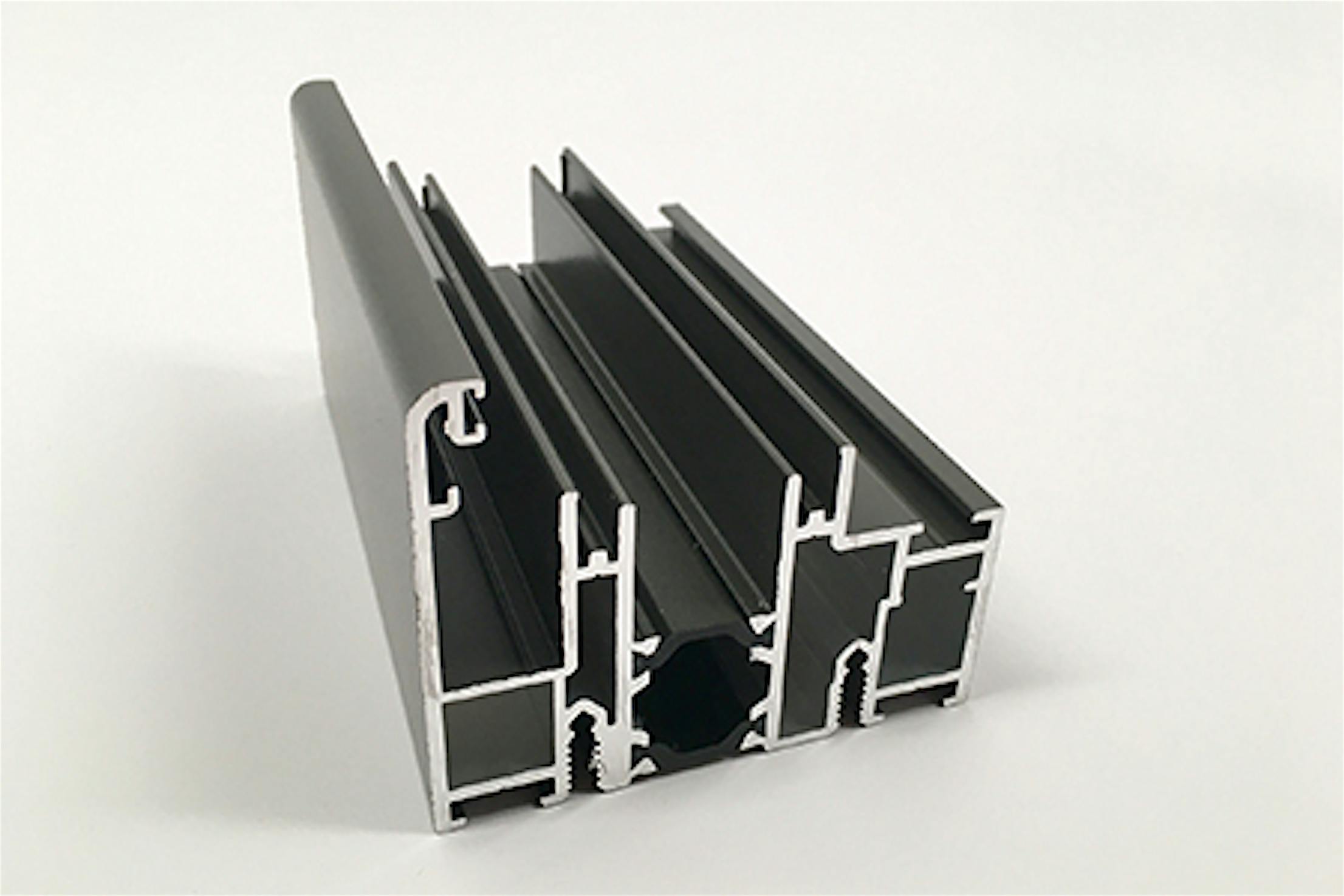

Reinforced structural posts and impact rated laminated glass provide unparalleled strength. Dual stainless steel elevated running carriages within the reinforced structural posts are unaffected by track debris and lie above the water run-off level.

See Bear-Resistant Glass Doors

The NanaWall SL73 features a door panel depth of 70mm utilizing an advanced thermal strut that provides comfort for all climates and excellent sound control.

Extreme Weather Resistant

Energy-efficient by design, our glass walls keep the elements at bay, ensuring that even as seasons or temperatures change, your interior comfort will always remain the same.

Certified Testing Standards

NanaWall products endure the latest AAMA testing standards for air, water, structural, and forced entry.

Highly Energy-Efficient

Designed to keep the elements at bay, holding warmth inside while acting as a transparent barrier to the weather outside.

Materials Transparency

This product contributes to multiple LEED rating systems and has HPD certification.

Download Declaration Documents

Test Results

NanaWall SL73 has been independently tested for air and water penetration resistance, structural deflection, and forced entry.

Florida Product Approval # FL20107

See Air, Water, Structural, Thermal, and Forced Entry Results

Completely Impact Rated

Many approved systems are limited to outward opening and are not approved for areas that need protection from water. The NanaWall SL73 offers a complete impact rated system, allowing both inward and outward opening systems to qualify, while also providing protection from water penetration.

What Our Customers Have to Say

Tequesta Residence

The indoor /outdoor environment was exactly what the client and architects envisioned for the living area and guest bedrooms and the top-hung, hurricane approved systems allowed for a continuous flooring material both inside and out.

Palm Island Residence

The modern architecture of this Palm Island residence is complemented by the clean lined, NanaWall SL73 Aluminum Framed Thermally Broken Hurricane Approved Folding System which is used within four openings on the façade.

"The weather in South Florida is notoriously intemperate. The cabana—with the assurance of its NanaWall opening glass wall—provides security from a passing thunderstorm."

— Kathleen Allen, Contractor

50 standard colors that come at no additional cost, with an additional 200+ colors to choose from.

See Finish Options

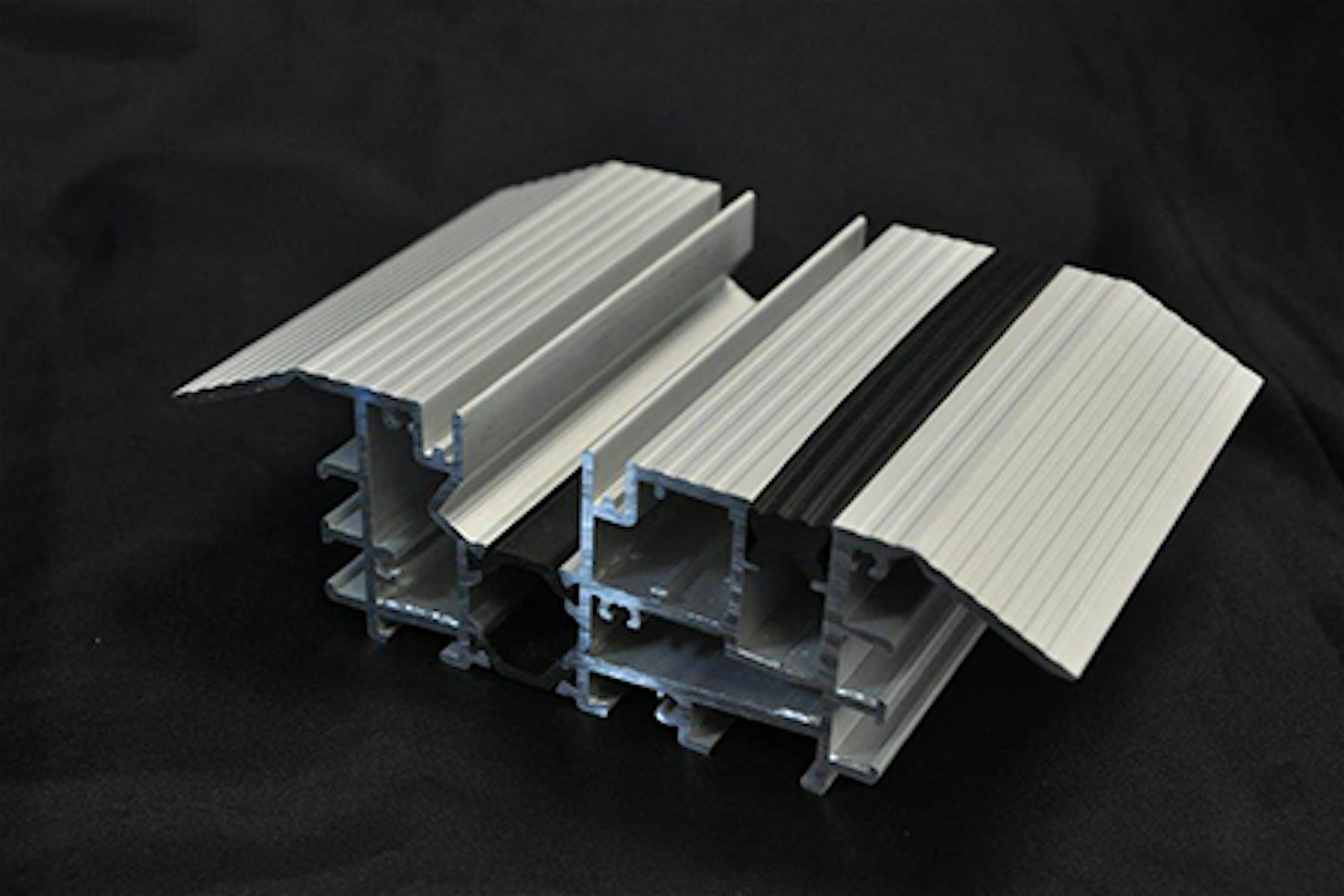

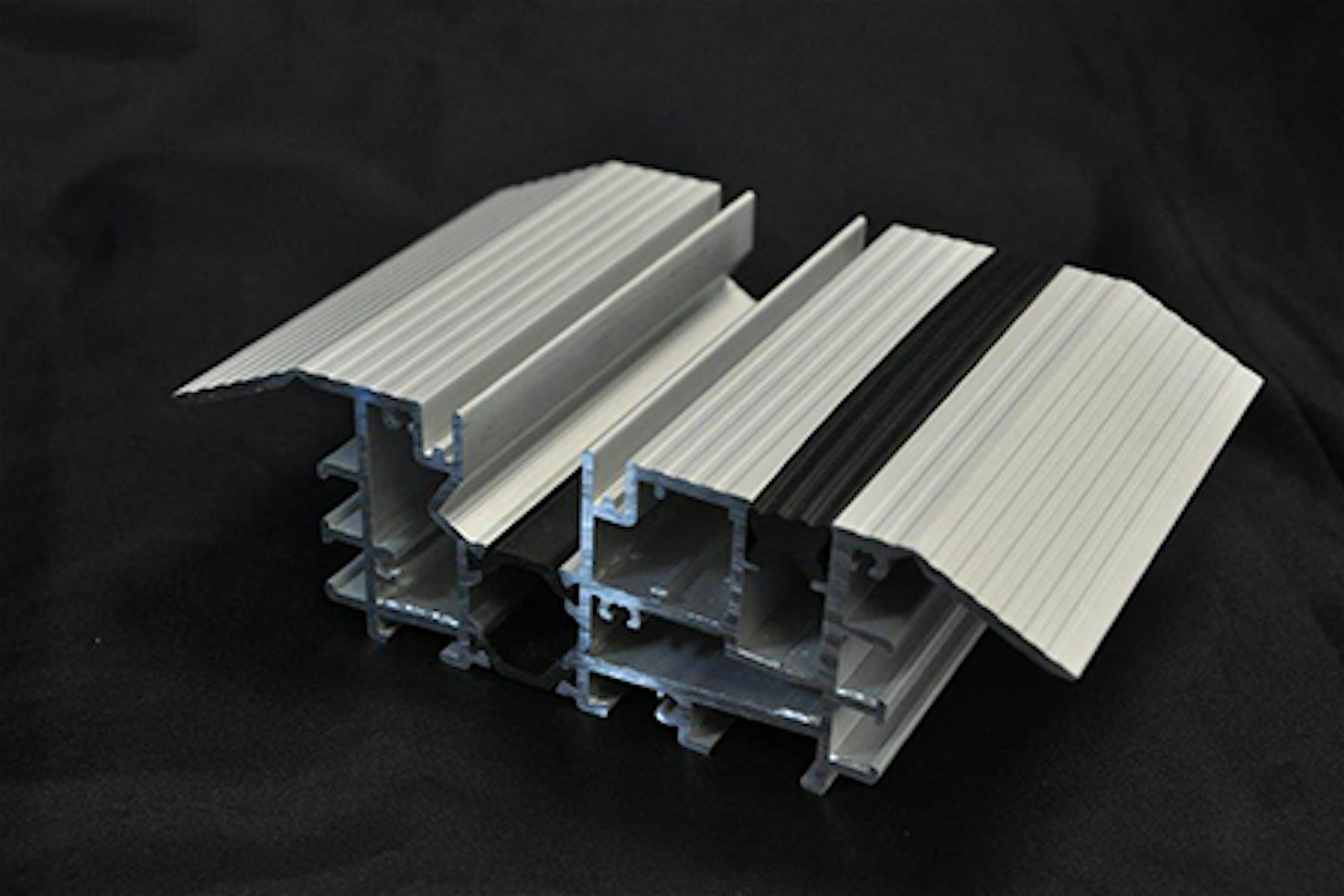

SL73 is available in three options: High Performance, Low Profile Saddle and Low Profile Saddle with UniverSILL®.

See Sill Options

Units can be supplied glazed with either annealed or heat strengthened 7/16" single impact glass or 1 1/8" insulated impact glass. According to the Dade County approval and engineering analysis, heat strengthened glass needs to be used for larger sized panels and/or higher design windloads; see product approval details. Please contact NanaWall for many other types of glazing that are available.

See Glazing Options

Stylish Handles in Multiple Finishes

Our handles are both functional and stylish and can be customized to accentuate your space and reflect your style.

See Handle Options

Locking for Maximum Security

Standard to the system is concealed locking between folding panels that operates with a 180° turn of a flat handle.

See Locking Options

Retractable Screens

A retractable screen add-on is perfect for blocking bugs while providing privacy and fresh air. Screens are not available through NanaWall Systems.

Retractable Screens

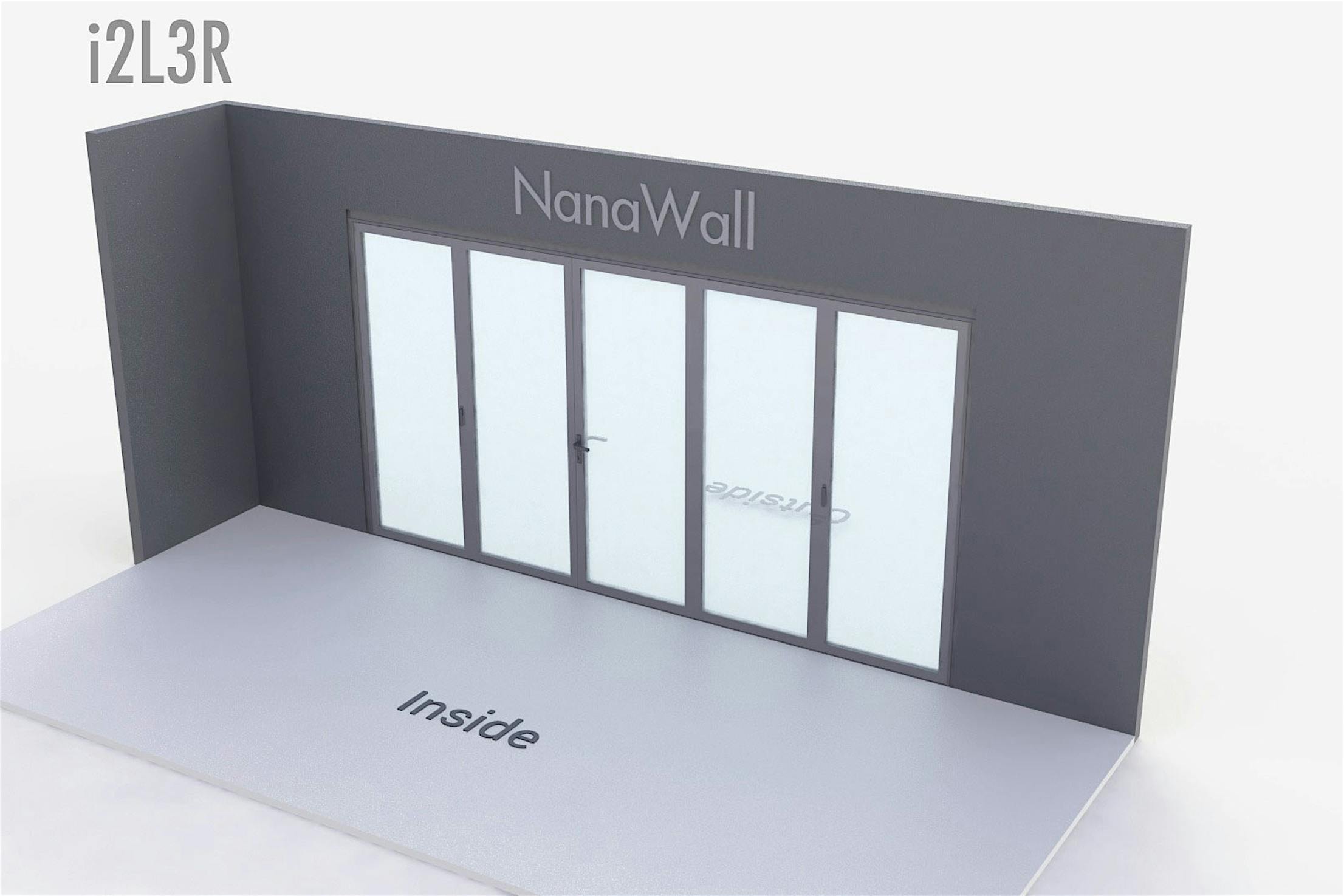

All standard configurations.

Explore limitless possibilities with our systems. Design and customize systems using our 3D CAD/Revit/Spec Configurators or contact our dedicated design team for more possibilities.

More ConfigurationsWe consider ourselves your partners from day one. Connect immediately with a NanaWall expert to answer your questions and explore how we can support your project.

(866) 210-4285

Monday - Friday: 7 AM - 5 PM PST